Pre-assembled cables for drive technology

NORD Drivesystems provides complete drive systems from a single source. NORD cooperates with HARTING to provide pre-fabricated pluggable cables for power supplies and controllers, in addition to their drive consisting of gear unit, motor and drive electronics. The result is a genuine system solution that enables facility operators to save 15 to 20 percent of the time required for assembly and commissioning at the construction site.

NORD Drivesystems is one of the global industry leaders in drive technology, providing mechatronic solutions for geared motors, electric motors, industrial gear units, frequency converters and motor starters for decentralised drive controllers and for switch cabinet assembly.

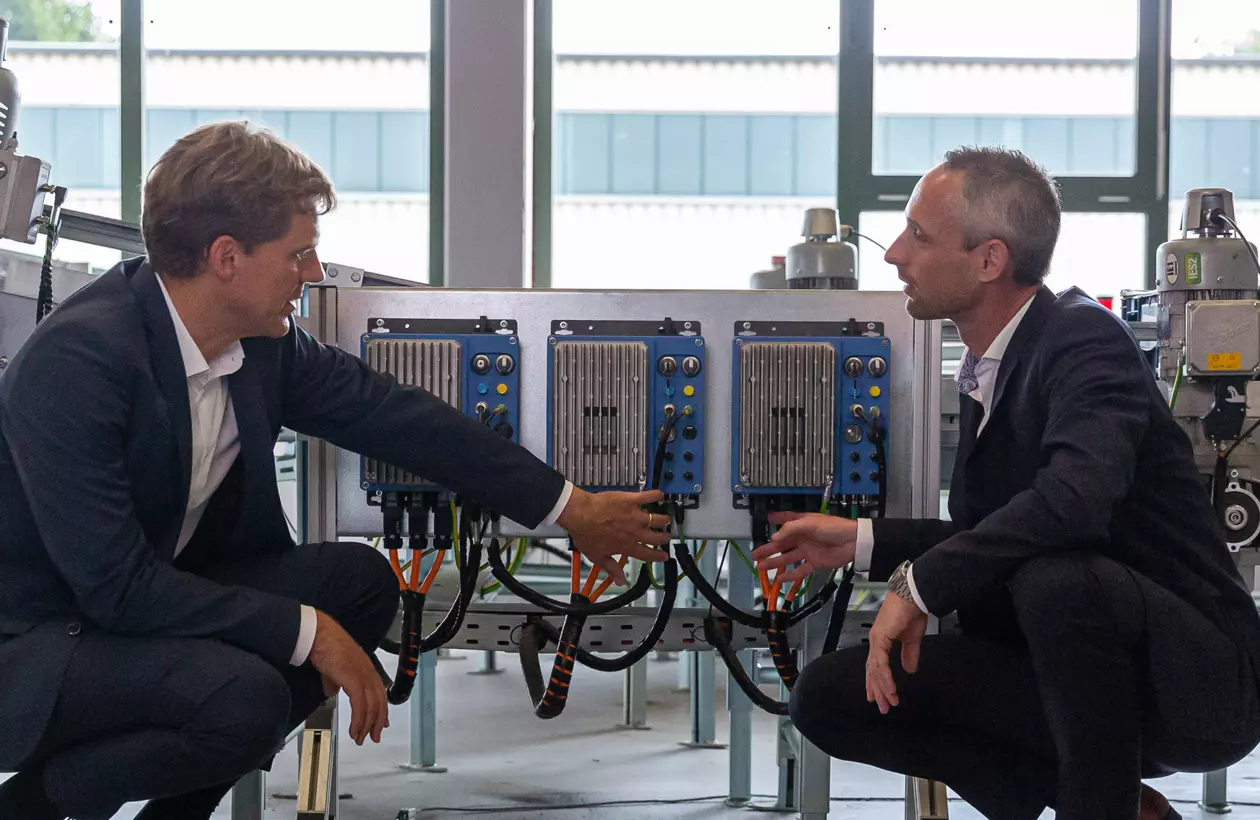

"We supply many of our drives with pluggable connection technology and are now expanding our portfolio to include the appropriate pre-assembled cables so that our customers receive a genuine system solution," explains Dirk Boysen, Head of Business Development, Electronic Drive Systems at NORD Drivesystems, in describing the genesis of their cooperation with HARTING.

The need for pre-assembled connecting and control cables

Solutions like those for NORD cannot be developed in parallel along with our day-to-day mass business. At HARTING, we have specialists in-house just for this.

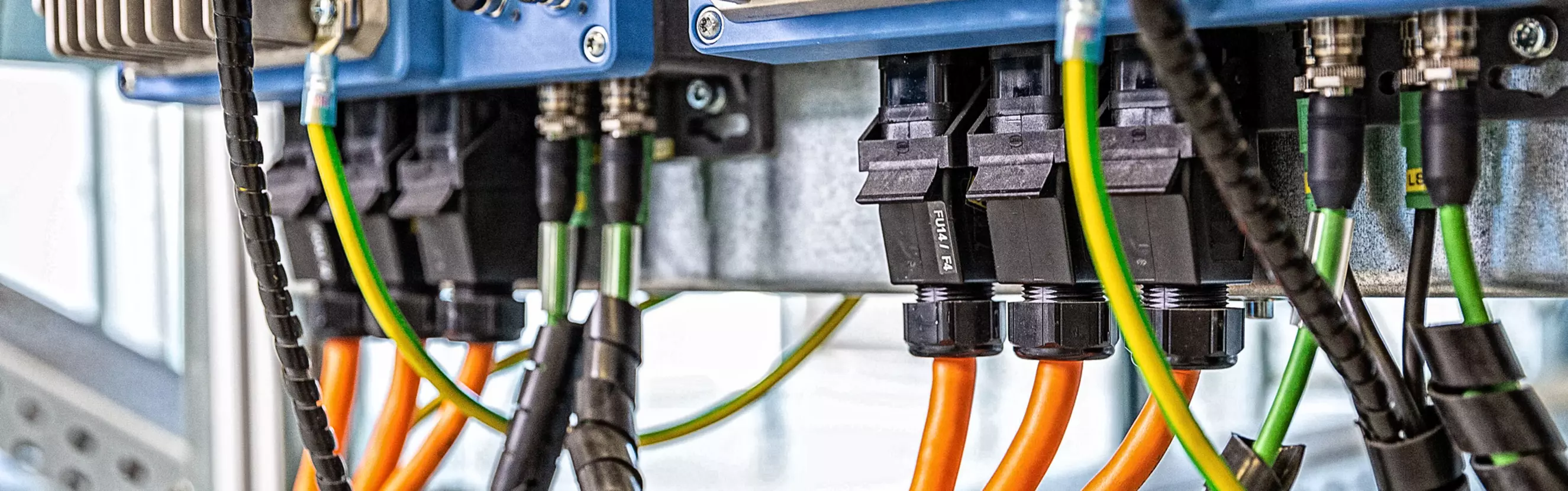

Customer response to this pluggable connection technology has been very positive. That is because plug-in cabling does not require any specialist staff at the construction site. This system solution has the mutual benefits of reduced installation time and improved wiring quality. Many drives are usually installed under time pressure during the initial commissioning on the construction site. Mistakes can easily happen. The cables often have to be separated properly under adverse conditions, the cable shield must be applied in accordance with EMC standards, and the wires must be connected properly. All of these potential sources of error can be avoided by using the pre-assembled termination technique. The effort and expense involved with assembly, commissioning and subsequent service calls is also significantly reduced so the advantages of the "system cable" component.

To achieve outstanding solutions, it is not only important to focus on key areas of expertise, but also to progress towards opening partner networks. Focusing and opening lead to successful partner networks. (...) I see partner networks as the key tool for Integrated Industry to create value for people.

Philip Harting

CEO of HARTING Technology Group

A standard cable would not be sufficient for the requirements of the NORD motor cable. A solution had to be found for the shielding of the plastic housing around the frequency converter. In order to avoid impermissible radiated interference and to meet the requirements for electromagnetic compatibility (EMC), an optimal 360° shield connection was developed within the connector housing. "We have qualified several suppliers for our special solution. HARTING's implementation had the best quality and their commercial offer was also right on target, ”said Mathis Kosbab, Product Manager of Electronic Drive Technology, explaining the collaboration with HARTING.

Solutions like those for NORD cannot be developed in parallel along with our day-to-day mass business. At HARTING, we have specialists in-house just for this. which specializes in customer-specific solutions.

Certified motor cables for NORD drives

In this project, NORD provided the specifications for the cable and the assemblies; the specialists from HCS then modified the connector housing and implemented the offer. As a UL-certified manufacturing company, HARTING was also able to deliver the safety certificates and demonstrate compliance with standards for the European, American and Asian markets. For this, HCS carries out approval tests in its own accredited test centre. Functional and service life tests are carried out according to customer specifications (e.g. for IP protection classes, current carrying capacity, vibration resistance, and the quality of data and signals).

"HARTING delivers the shielded motor cable in outstanding quality. The cooperation with HCS on data sheets and drawings, as well as their quick response to offers and delivery time inquiries were what convinced us," says Mathis Kosbab.

The assembly time is reduced by up to 20 percent

"Thanks to the pre-assembled connection and control cables, our customers can significantly reduce their assembly and commissioning times. We guarantee the quality of this system solution and assume the technical responsibility," explains Dirk Boysen in summarising the advantages.

"Thanks to the pre-assembled connection and control cables, our customers can significantly reduce their assembly and commissioning times. They are also ensured of the system safety because the cabling is specially designed for our devices. We assume the technical responsibility," explains Dirk Boysen in summarising the advantages. He also points to the improved maintenance and the associated reduction in downtime costs. "If a cable in the facility now becomes damaged, it can be replaced more easily and the fault can be eliminated more quickly."

For over 50 years, NORD DRIVESYSTEMS has been developing, producing and selling drive technology. They have more than 4,000 employees and are one of the leading international full-range suppliers in this industry. In addition to their standard drives, NORD supplies application-specific concepts and solutions for special requirements such as energy-saving drives or explosion-protected systems. NORD has its own local subsidiaries and sales partners in 98 countries around the globe.