June 19th - 21st 丨 Meet us at South China International Industry Fair

June 19th - 21st 2024丨 Meet us at South China International Industry Fair

South China International Industry Fair will be held on 19-21 June 2024 at Shenzhen International Convention and Exhibition Centre (Bao'an New Venue), which is a platform to showcase the latest achievements in the fields of industrial automation, intelligent manufacturing, industrial robotics, and industrial Internet of Things (IoT). With the promotion of the Made in China 2025 strategy, Industry 4.0 and Internet of Things have become an important direction for the development of the manufacturing industry.

In this context, as an industry leader, actively involved in the field of industrial connectivity for more than thirty years, HARTING will bring many star products and solutions to meet with all industry players in this South China International Industrial Expo, and HARTING will be committed to providing customers with efficient and reliable solutions in the future, and help China's manufacturing industry to develop.

Opening Hours: 19th June - 21st June 2024

Exhibition Venue: Shenzhen International Convention & Exhibition Centre (Baoan New Hall)

Booth Location: 12H-B118

HARTING Booth

Smart Devices Smart Connectivity

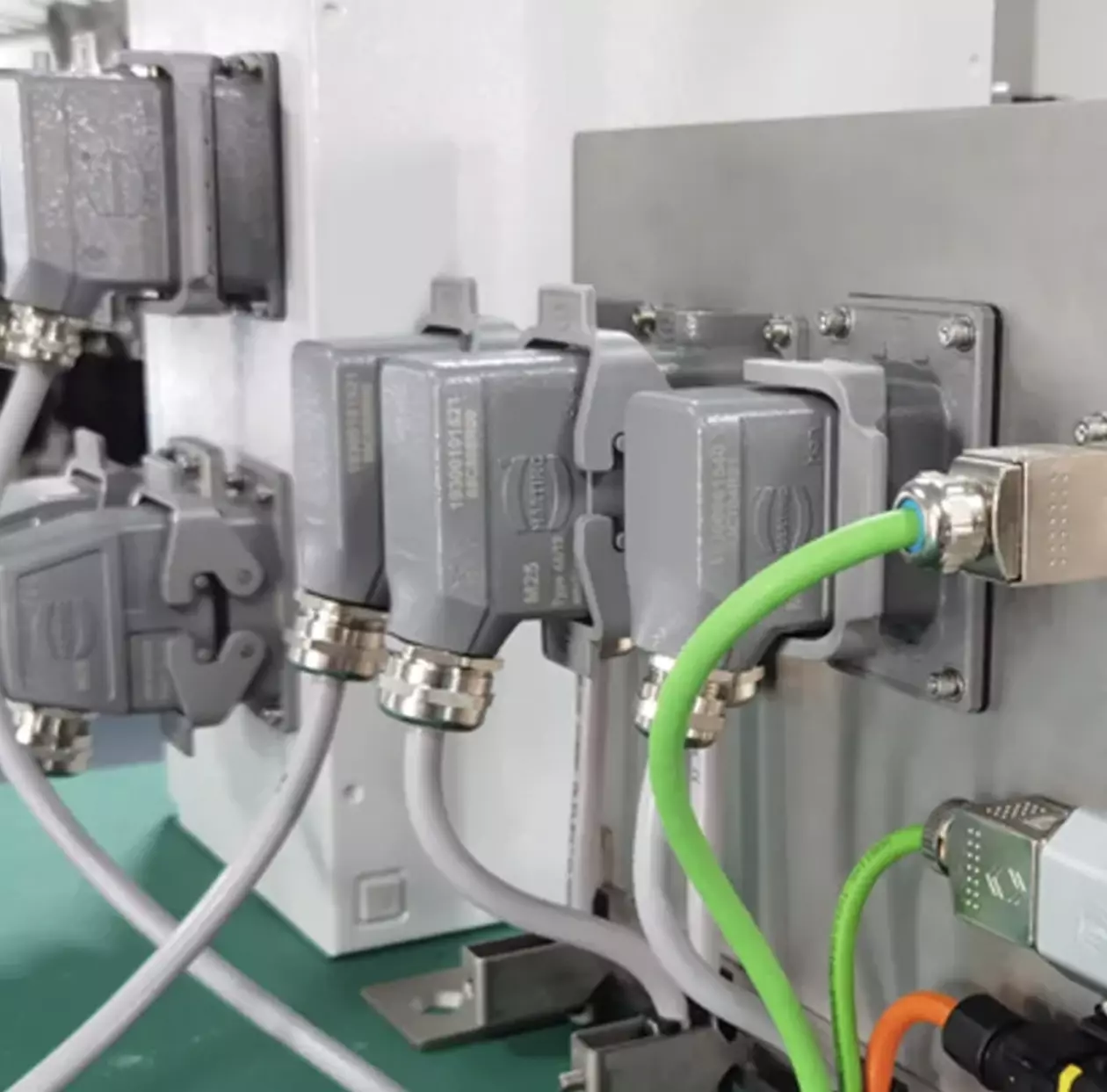

Han Modular connections

An overview of the advantages that modular connections bring to the design of electrical cabinets:

Integration of multiple connectors into one unit

Reduced installation time

Significantly reduced space requirements

Cost savings on components and the entire system

Future-proofing through flexible enhancements

Lithium Connection Applications

As a manufacturer of listed and recognised product options for UL 508 applications, Halting has worked closely with UL to fully test and certify HARTING connectors for use in UL 508A electrical cabinets. This means that lithium brands can confidently use HARTING connectors without the need for additional safety testing, thus saving time and costs.

Han-Modular® Domino Modules

HARTING will be showcasing its latest Han-Modular® Domino Module, the next stage in the evolution of modular connectors. The Domino Module meets the industry's need to save installation space and weight by integrating different transmission types in a single module, saving up to 50% of installation space.

Han Push-In Technology

To further improve field installation efficiency, HARTING has introduced Han Push-In wiring technology, which reduces assembly time by up to 30%. Push-In technology expands the Han® industrial connector portfolio, maintaining consistent quality and ruggedness through quick and easy connector assembly.

Benefits at a Glance:

Reduces assembly time by up to 30% by inserting the conductor directly into the needle cavity.

Tool-less wiring for easy operation

Cost savings

Maximum flexibility for a wide range of conductor types

Compatible with similar products using other wiring techniques

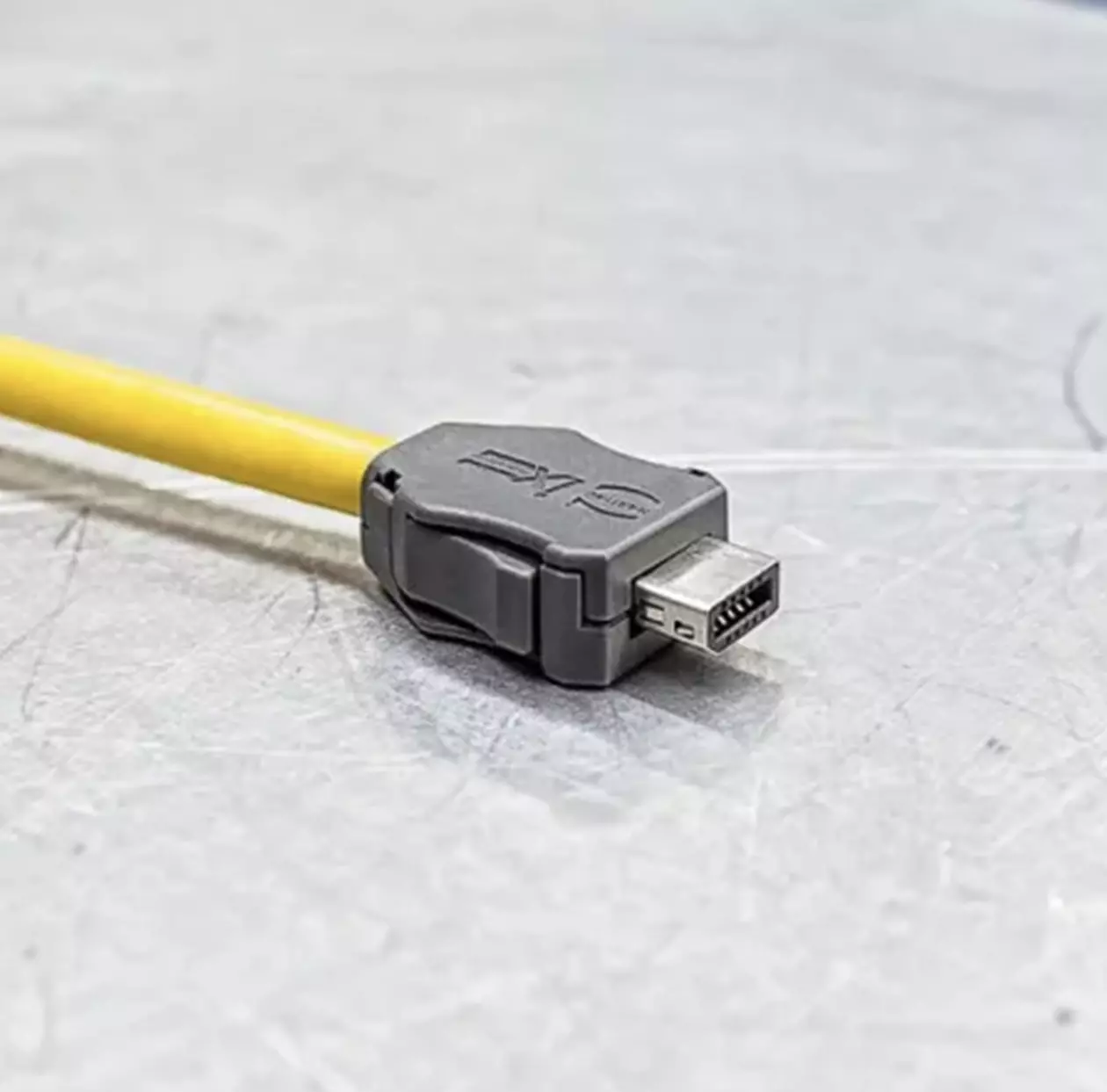

ix Industrial® Ethernet Connectivity Solutions

The ix Industrial® from HARTING is the answer to the challenges of Industry 4.0 and the Internet of Things. Standardised according to IEC 61076-3-124, this interface sets a new standard in durability and is a miniaturised alternative to RJ45.

Benefits at a glance:

Adapted to the needs of Industry 4.0 and the Internet of Things (IoT)

Miniaturised design saves space

Compliant with IEC 61076-3-124 standard

High durability and reliability

Delivers Class 6A performance for 1/10Gbit/s Ethernet

Han® Protect protective connectors

The Han® Protect connector developed by HARTING simplifies the protection structure of the infrastructure and reduces the installation space required in the control cabinet. The Han® 3 A connector uses the M12 A coding connector, which is widely accepted by customers for the input and output of I/O signals, as a mating interface and incorporates a 5x20 mm miniature fuse. The latter ensures protection of the downstream control unit in the event of a fault. The connector is mounted on the outside of the control cabinet so that blown fuses can be identified by LEDs without opening the cabinet and replaced without tools. This eliminates the need for a large number of fuse terminals.

Benefits at a glance:

Saves up to 30% of cabinet installation space

Simplifies maintenance processes

Reduced maintenance time

Higher availability