Digitalisation of local network stations (LNS)

The term “smart grid” is no longer unfamiliar and, in short, refers to a digitally based electricity network that is designed to function reliably and as efficiently as possible to ensure security of supply for end consumers.

Part of this electricity grid are so-called local network stations (LNS), which can be found throughout the country. The more than 600,000 installed LNS can be recognised as small grey houses, often located directly in the neighbourhood, which frequently emit a low humming noise. These LNS are the link between the medium voltage level and the low voltage level (400 V/230 V) used by end consumers and are basically nothing more than a transformer in a concrete house, ideally surrounded by electronics for monitoring and control. Mostly planned and commissioned in the previous decade or century, many LNS lack any possibility of monitoring and controlling the low-voltage network using digital solutions. However, this is highly relevant today due to the increasing feed-in of renewable energies and changing consumer behaviour (home offices, e-mobility, heat pumps, etc.), as electricity consumption and generation must be balanced at all times. A fault in the low-voltage network or even a failure of an LNS is directly noticeable to the end consumer and is often only detected by the responsible network operator when the affected end customer reports it.

This was reason enough for HARTING to develop a digitalisation unit in collaboration with one of the leading digital service providers for distribution network and metering point operation, E.ON Grid Solutions GmbH. This can be installed as a retrofit solution, thereby enabling the smartification of existing local network stations.

The field of application for this solution (“neonpulse” at E.ON Grid Solutions) is the low-voltage side of the LNS in the network area of E.ON's German distribution network operators. The intended use of the retrofit solution for local network stations is the acquisition, conversion and forwarding of measurement data.

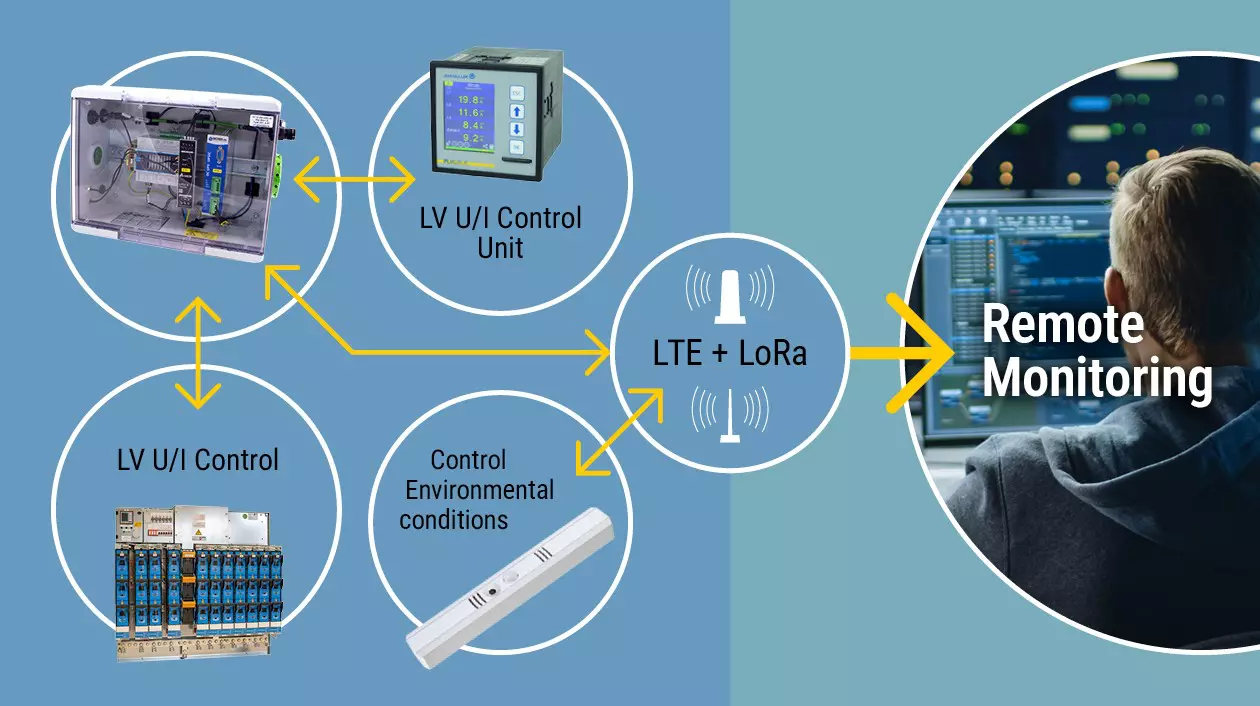

For this purpose, existing multi-metering devices and NH fuse switches (low voltage high current) with measuring function in the LNS are read out via HARTING RJ45 interfaces and HARTING communication cables via Modbus RTU. The measurement data is sent to the E.ON digital platform “e.IoT” via mobile radio using an IoT gateway. Short power failures can be bridged by combining a power supply unit with an uninterruptible power supply, allowing data acquisition and transmission to continue for at least 60 seconds after a power failure.

This automatic data acquisition leads to a new level of observability of the low-voltage side in existing LNS. In addition, the gateway records the measurement data from an environmental sensor located within the local network station at 15-minute intervals. Measurement data such as temperature, humidity, light intensity and movement within the LNS are also processed and sent via LoRaWAN to the gateway and then via LTE mobile communications to the data cloud. This information can be used to determine valid temperature profiles within the LNS for better design of electronics and to monitor unauthorised access to the LNS.

All in all, it can be said that the retrofit solution, which is a joint project between E.ON, HARTING Germany and HARTING Customised Solutions, communicates a comprehensive status of the LNS to the E.ON data cloud using modern wireless technologies. This means that any malfunctions or faults within the station can be identified quickly and resolved in a timely manner.

Compared to building new LNS with intelligent network technologies, this solution also offers a time advantage, as it can be implemented more quickly and cost-effectively. It therefore offers both economic and ecological advantages, as new construction and the resulting larger carbon footprint are avoided.

Ralf Reicks

Position: Project Engineer Energy

- Department: Global Project Engineering

- Company: HARTING Technology Group

Dr. Thomas Schröder

Position: neonpulse Project and product management (material and supplier management)

- Company: E.ON Grid Solutions GmbH