Connectors simplify switch cabinet construction

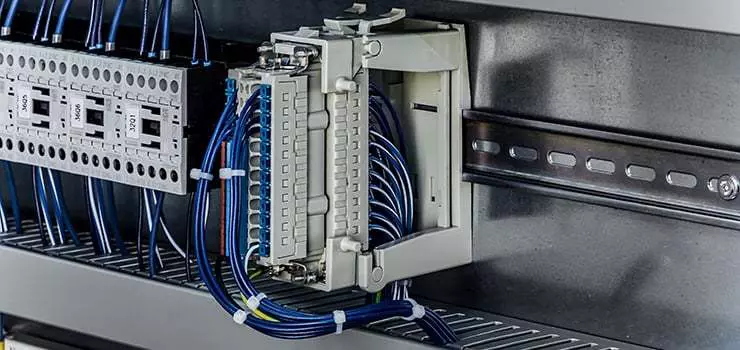

Thanks to new rear mounting options, connector inserts can be installed from the inside of the control cabinet. Many installation processes can be shifted to the pre-assembly stage, thus helping to save expensive technician hours at the turbine assembly.

The search for savings opportunities is a central topic in the wind industry. All parts of the value chain must be examined, if wind turbines are to be offered competitively in different markets. As a rule, the focus is put on cutting electricity production costs, which is achieved by reducing capital and investment costs (CAPEX), and on operational expenditures (OPEX).

However successful the strategies may be, the required reductions cannot be achieved exclusively by enforcing lower purchase prices for materials and components. Instead, new ideas and processes have to be found and implemented along the entire value chain. The component suppliers must be more intensively involved in the manufacturing processes of the wind industry. Especially promising is cooperation in the field of switch cabinet construction.

Pre-assembly shortens expenses for experts in the field

The rear-fit housings support the installation of switch cabinets. Contact inserts of connectors can be mounted entirely from inside of the control cabinet into a bulkhead housing at the surface. This option is called rear mounting and it is available for both metal Han® B and plastic

Connectors with inserts that can be rear-mounted open up a significant optimisation potential for switch cabinet manufacturing, installation and operation. They save time for termination, reduce errors (by offering coding options) and lead to cost savings, e.g. when it comes to second or third installation processes or the removal of control cabinet parts.

Additional time savings via rapid termination with pre-loaded cage clamp

The rapid and tool-less termination technique of Han® ES Press increases the advantages of the rear fit option. Compared to standard termination technologies, the time required to assemble a connector can be reduced by half. Han® ES Press is a family of inserts that is based on the proven cage clamp technique.

You only have to strip the wires and put them directly into the Han® ES Press insert. Then you have to push-in the blue actuator, and the pre-loaded cage clamp is tightly enclosing the wire, thus ensuring a reliable and vibration-proof connection. No need for crimping additional contacts; no special tools required.

Easily bridging contacts in inserts

In a control cabinet, you can find many terminal blocks that multiply or collect electrical wires with the same voltage level in electrical nodes; the number of cables is high and space for terminal blocks is limited. Now, with Han® ES Press, the electrical nodes or the potential multiplication can be set up directly at the insert. The wires are easily bridged by inserting the jumpers into the insulation body.

The use of various longitudinal and transverse bridges reduces space requirements and saves installation time. In addition to potential multiplication, they allow the construction of star and delta circuits, e.g., for connecting sensors. Manufacturers of switch cabinets will benefit from faster termination processes in series production and from quicker wirings, while retaining the full functionality in field installation, no matter whether stranded wires are used or wire ends – with or without ferrules. The named benefits are valid for all terminal boxes used in wind turbines.

If both solutions are combined – the rear-fit hood or housing and the Han® ES Press insert – they enable the cabinet manufacturer to save time, as they shorten the assembly process and help saving space (especially due to the bridging functionality). These advantages are a complementary to all the other advantages of using connectors in the wind industry. In general, they support the realisation of cost savings along the entire value chain of wind energy.

Your benefits at a glance:

Savings of time and cost due to rear mounting options

Separate pre-assembly of entire cable harnesses possible

Reduction of manufacturing cost by better division of labour

Additional time savings by using Han® ES Press rapid termination

We believe that our suppliers are long-term partners, from last one decade we are working with HARTING. And particularly for India, we have started working with HARTING from 2021 and we’re using different, 80 types of connectors from HARTING, which is used in our nacelle and hub. HARTING offer the robust design, the high-quality product with performance and with sustainability, and also with use very ease to maintenance, as it is plug & play.

Prafullakumar Dhole

Head of Procurement

Product Sample Request

Would you like to benefit from time and cost savings by up to 30% enabled by the new rear mounting options? Request your free sample to get a first impression.