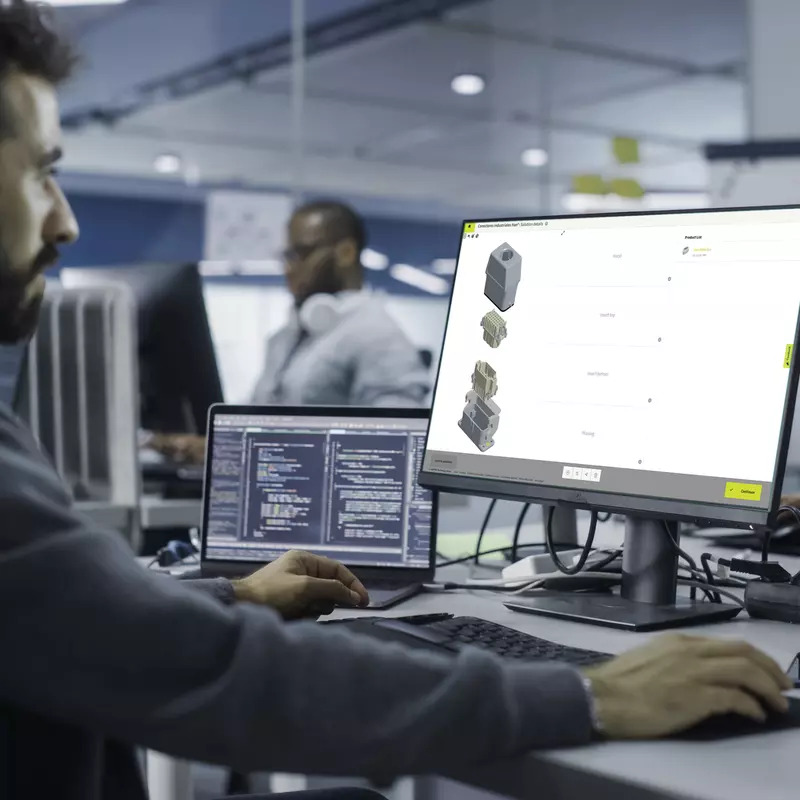

Rectangular connectors

Quick and easy handling, robustness, flexibility in use, a long life cycle and, ideally, a tool-free assembly - whatever you expect from a connector – Han® rectangular connectors won’t disappoint you. You’ll get even more.

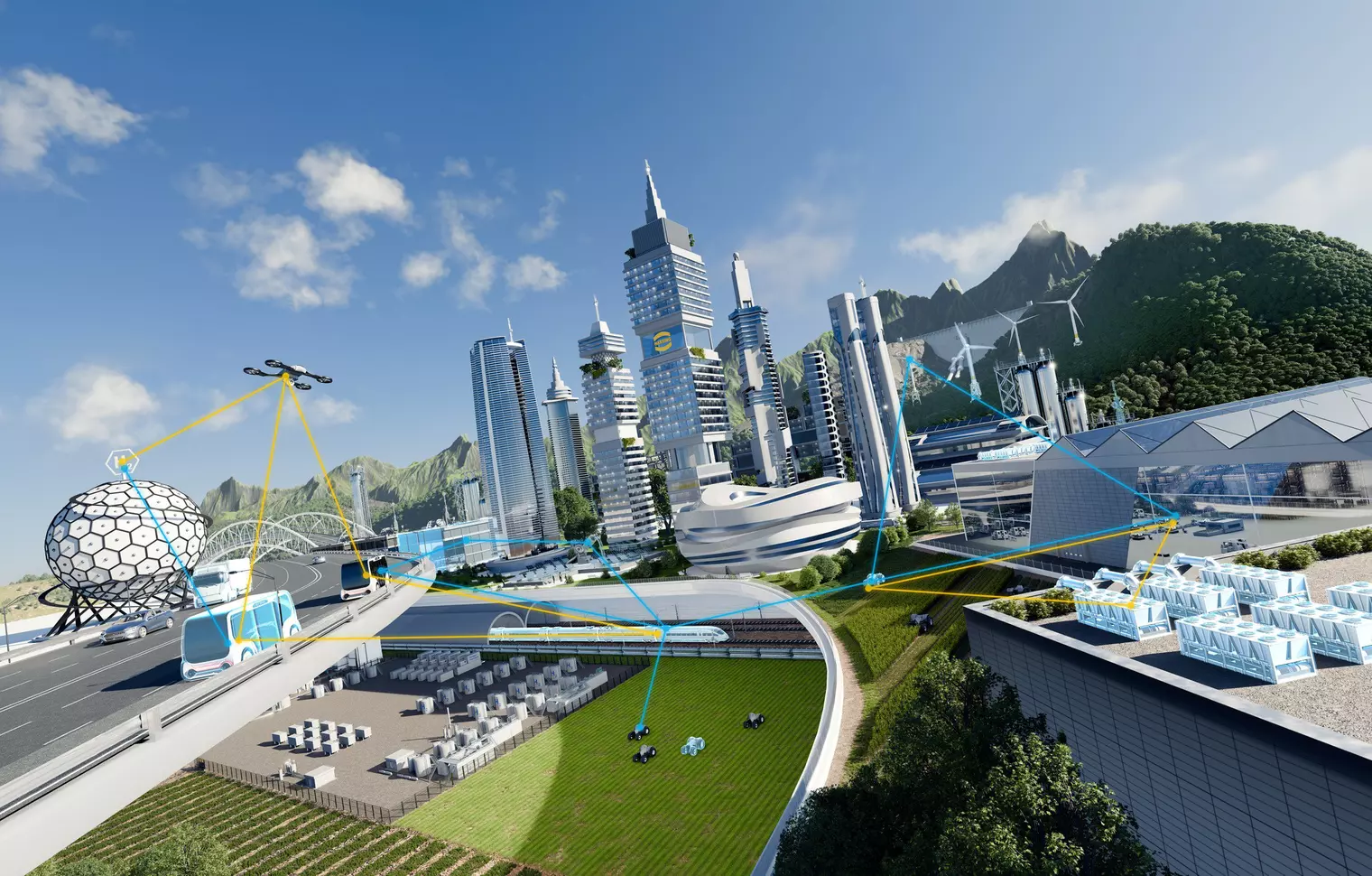

Connecting you to the All Electric Society

Welcome on the way to a sustainable future: Discover with us the big picture of an electrified, digital world - for a climate-neutral future.

The HARTING Technology Group

100 % owned by the Harting family, around 6.000 employees, Euro 940 m in turnover, 14 production plants and worldwide 42 sales companies. Learn more about the HARTING Technology Group