Cable assemblies for decentralized frequency inverters from SEW-EURODRIVE

Partnership-optimised industrial applications with reliable and powerful cabling solutions.

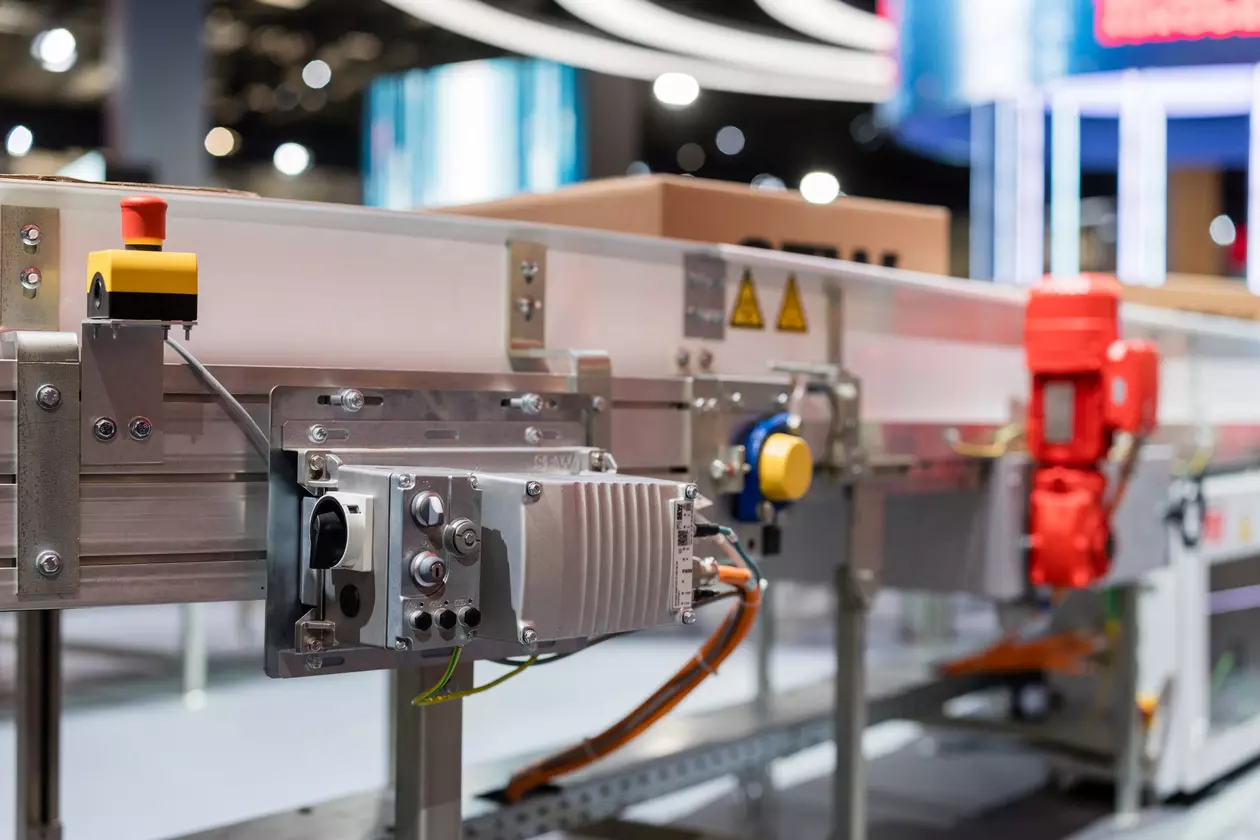

Frequency inverters build the heart of modern logistics. Wherever goods are moved, for example in intralogistics, on baggage conveyor belts or in postal distribution centres, but also in industrial applications such as automotive production or in the beverage and food industry, they dynamically provide the necessary drive and correct positioning.

Secure connection with Han® connectors

The decentralised frequency inverter MOVIMOT® flexible in the logistics version is equipped with plug connectors from the Han® series on the device side.

With the decentralised frequency inverter

Frequency inverters are equipped with interfaces for supplying electrical power and processing signals and data. This enables error-free and loss-free connection worldwide.

When setting up conveyor lines, but also in the event of servicing, time is one of the most important factors. The time required for the assembly and installation of electrical cables can be significantly reduced or eliminated if cables are pre-assembled.

Plug & play solutions minimise installation time

The use of pre-assembled cabling solutions from HARTING reduces installation time to the absolute minimum. All connection cables are manufactured to HARTING's highest quality standards and are 100 % tested – plug & play without time-consuming wiring work on site.

However, should field assembly be necessary, HARTING offers suitable connector sets consisting of housings, contacts, screw connections and other needed components.

Further accessories for power transmission and energy distribution, based on the robust Han® connector series, are also available directly from the HARTING e-Shop.

Pre-assembled cables enable inverters to be connected via plug & play with minimal time and effort.

Your Advantages

Decentralised automation enables automation to be moved from the control cabinet directly to the field

Easy handling: simple configuration and quick commissioning

Time savings during installation: pre-assembled cables reduce installation time, no complex wiring required on site

Minimal downtime during maintenance: quick and easy exchange reduces downtime

High quality and safety: connection cables are manufactured to the highest quality standards and are 100 % tested

Flexibility in case of service: if assembly in the field is necessary, suitable plug sets are available

Extensive accessories: components can be ordered directly from the HARTING e-Shop

SEW-EURODRIVE maintains a professional and efficient collaboration with HARTING. Reliable communication and the high quality of HARTING’s solutions support us in implementing our projects successfully and with clear focus.

Annabelle Becker

Product Manager MOVIMOT® flexible