Quality - for a lifetime!

Our HARTING connectors are at home all over the world. Whether in India, Brazil or Denmark, they all have one thing in common – our quality standard. This is ensured by our independent testing and inspection facilities at Corporate Technology Services (CTS) in Espelkamp and Zhuhai. Before our products and solutions are used by customers, they must pass extensive quality tests in our test laboratory.

The requirements are based on international standards, which are supplemented by HARTING specific requirements based on customer needs, years of market experience and reliability studies. Because the HARTING Group's quality standards do not end with delivery – they must prove themselves in daily use.

Goals of the HARTING Corporate Technology Services (CTS):

Efficient qualification of processes and products through comprehensive provision of measurement and testing technology, as well as technical expertise.

Rapid market launch of products through early involvement in the development phase and support by business units.

Ensuring the quality of the HARTING Technology Group's international testing setup.

Technical communication and marketing support through knowledge transfer and presentations to customers.

Advantage of our internal HARTING laboratories: In addition to our testing expertise, we know the products and their market applications. This enables us to provide expert advice on the various testing requirements.

Stephan Middelkamp

General Manager Quality & Technologies

Test spectrum

Product release, effective qualification of processes and products

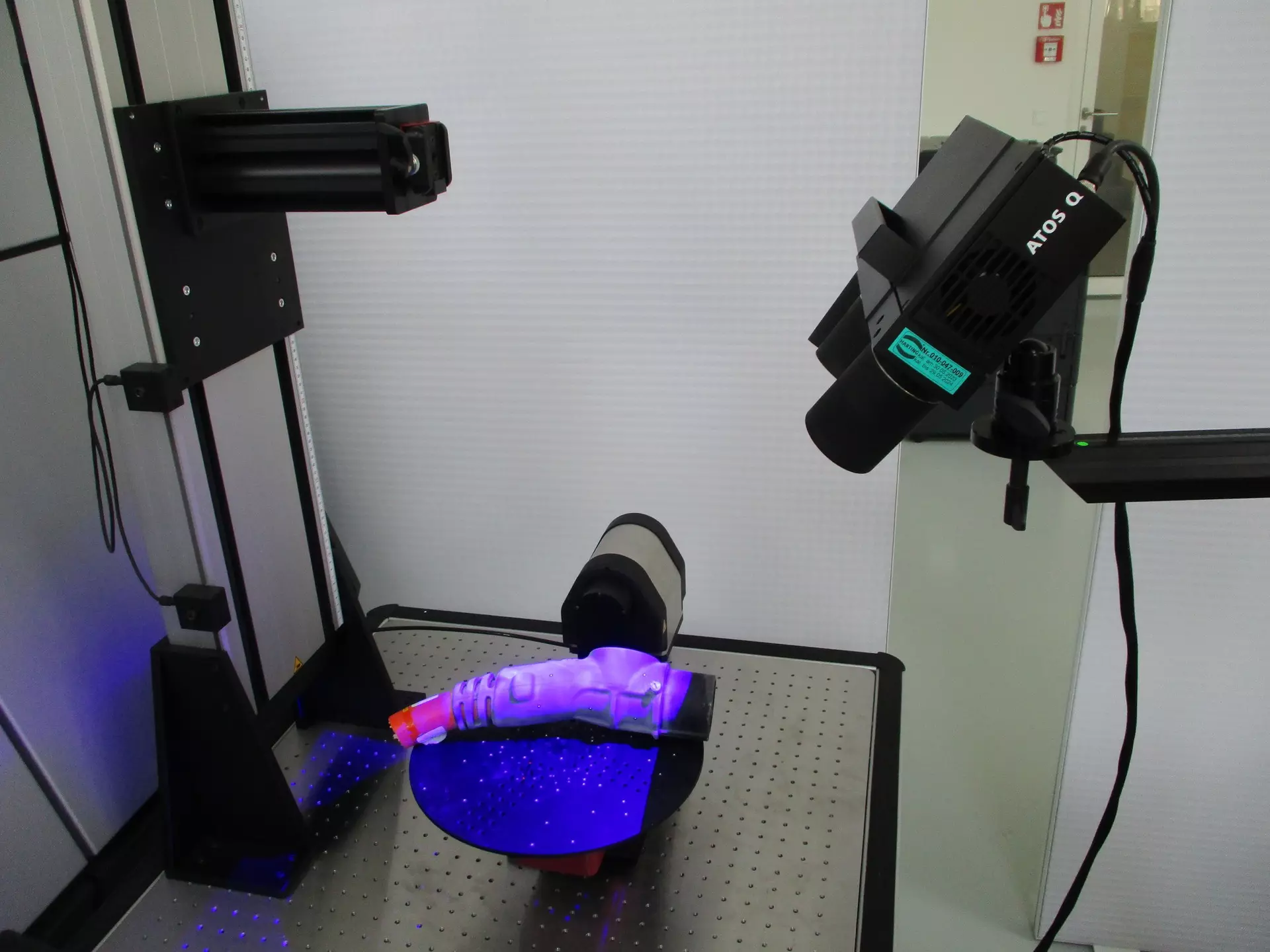

Computed tomography for component analysis and measurements Dimensionelle

Dimensional measuring technology (2D, 3D coordinatemeasurements)

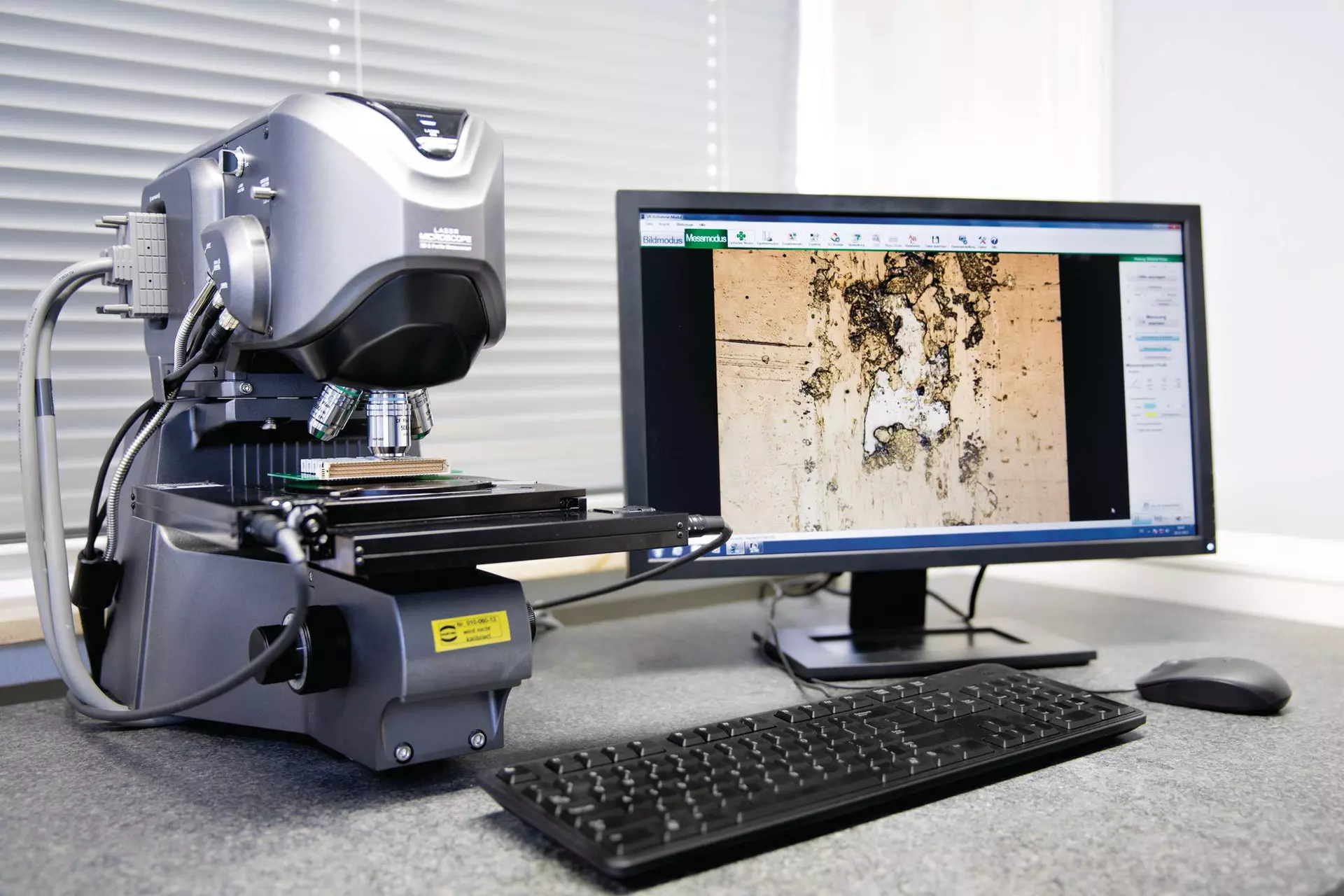

Surface and material analysis: light microscopy, X-rayfluorescence analysis, plastic analysis, scanning electronmicroscopy with EDX, Focused Ion Beam (FIB)

Dimensional, electrical, mechanical and reliability investigations on micro-electromechanical systems

Corrosion tests, IP tests, climatic tests

Electrical tests, mechanical tests

Vibration tests with climatic and electrical load

Tests of fibre-optic components and systems

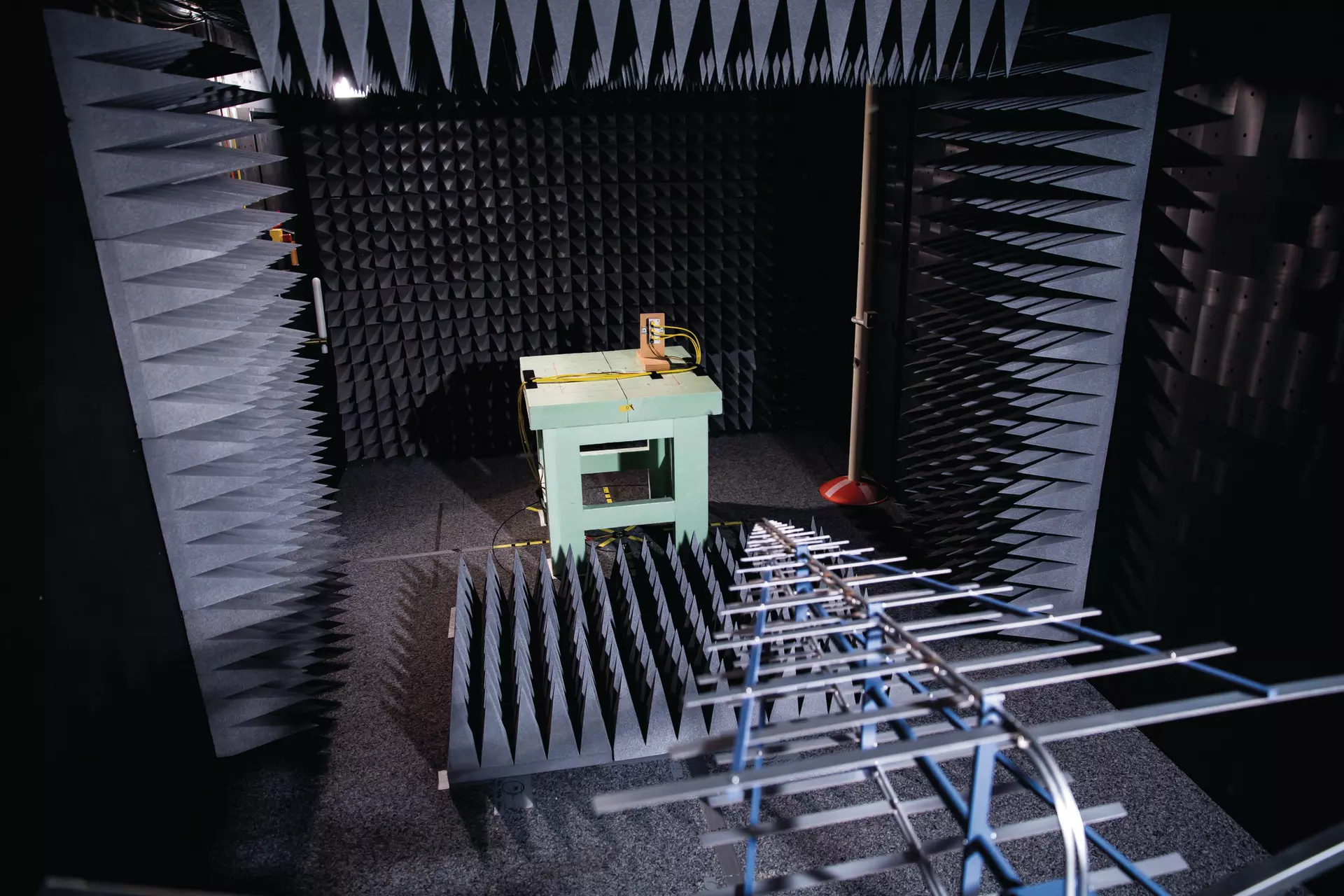

Electromagnetic compatibility (EMC-interference emission,EMC-interference immunity)

Signal integrity (Analysis in time and frequency domain)

Strip light scans

A selection of our testing and inspection equipment

The testing laboratory in Espelkamp, Germany

is accredited by DAkkS in accordance with DIN EN ISO/IEC 17025: 2018

The scope of testing includes electrical, mechanical and basic environmental testing, EMC and RF testing on electromechanical components and fibre optic testing, as well as 1-, 2- and 3-dimensional length measurements.

The accreditation only applies to the scope of accreditation listed in certificate annex D-PL-12148-01-00.

Accreditation Certificate

The current scope according to flexible accreditation can be found here:Current scope In addition, it is certified by UL as part of the

Client Test Data Programms and by VDE as part of the TDAP (Test Data Acceptance Programme) at level 2VDE Certificate

The testing laboratory in Zhuhai, China

is accredited by the China National Accreditation Service (CNAS) in accordance with ISO/IEC 17025: 2017.

The scope of testing includes electrical, mechanical and basic environmental testing.

The accreditation only applies to the scope of accreditation listed inthe certificate annex:

Accreditation Certificate

The current scope according to flexible accreditation can be found here:accreditation scope

Certificates for Testing and Laboratories

Discover our management system certificates for testing procedures and laboratory services.

Dr. Stephan Middelkamp

Position: General Manager Quality & Technologies

- Department: SSU QT

- Company: HARTING Stiftung & Co. KG