Digitalisation of production technology: The right interfaces for latecomers

“Existing business models are being challenged by digitalisation, and global markets are becoming increasingly volatile” [1].

These interrelationships, as well as the resulting transformations of business models and the associated risks, must be viewed in a very differentiated manner. The mechanical engineering industry in particular, with its typical structure of SMEs and “hidden champions,” is in a very good position worldwide to view digitalisation not as a threat, but as an opportunity to expand existing business models and, in the long term, to open up new markets using new technologies. Ultimately, it is clear to all business players that digitalisation ensures the long-term competitiveness of OEMs in mechanical and plant engineering.

What speaks in favour of the digitalisation of production technology

The path to digitalisation can only be successfully navigated in many individual steps. For those involved, it cannot be a question of all-encompassing collective functionalities, as described under the terms “IIoT,” “Industry 4.0,” “digital engineering,” and the like. Rather, it is about concrete approaches that can be used to increase the efficiency and cost-effectiveness of machines throughout their entire life cycle with as little effort as possible. And because automation in mechanical engineering has been driven primarily by digitalisation for decades, it is primarily the relevant OEMs who can successfully implement these approaches based on their core competencies. Only OEMs can implement concrete measures in a targeted manner that combine existing functionalities and systems with the most promising new control and data transmission technologies! [2]

Digitalization in industry is often mentioned in the same breath as the keyword “Industry 4.0.” This term stands for the 4th industrial revolution: thus, the disruptive potential of current technological developments is equated with the impact of the industrial use of steam engines, electricity, and computers. Successful players such as Amazon, Microsoft, and Google are often cited as striking examples of the force of change. For medium-sized machine and plant manufacturers, however, this development is seen as a threat, at least in part. The protagonists of digitalisation are trying to take the edge off this. Hans Beckhoff, founder and CEO of Beckhoff Automation, aptly pointed out during a Chamber of Industry and Commerce event in 2017 that change represents an opportunity for industrial manufacturing and that the pace of change is slower than initially assumed: "From today's perspective, the introduction of the steam engine seems like a revolution. However, it took more than half a century before its use in industry led to significant mass changes." The impact of digitalisation on industrial production today should be viewed in a similar way. It is triggering evolutionary development at all levels and in all processes. At the same time, Beckhoff emphasizes that this realization does not mean that we should sit back and do nothing! According to Beckhoff, it is the courageous who will be rewarded when they creatively develop new business models for production systems.

HARTING has analyzed its customers' implementation strategies and can only confirm Beckhoff's theories. In order to achieve lasting success with digitalisation projects, it is therefore advisable not to try to achieve everything at once [3].

Whether the development is revolutionary or evolutionary, those involved agree that data forms the basis for more rational processes – and that means all types of data. The slogan “Data is the new oil!” originally referred to “big data” or the storage and availability of consumer data. However, this characterization can certainly be applied to data in industry. To stay with the metaphor, however, the “new oil” still requires functional ‘pipelines’ and other structural elements. “Data is the new oil” describes the current situation of many machine and plant manufacturers who are in the process of revising the creation, processing, and transmission of data for their products.

The OEM's “data view” of production systems

OEMs are experts in many existing technological, machine-related data, in the use of this data in their own machine functions, and in advanced automation functions.

The increased use of the “internal intelligence” of automation components such as drives, smart sensors, actuators, or HMI systems with all associated data transitions is now also part of an OEM's standard toolkit.

In addition, all possible data transmission layers at the machine network or line level that use known data generation, machine, user, and process models are also considered proprietary company know-how.

However, in the spirit of digitalisation, not all of the data structures and transmission layers mentioned above that are part of the control and automation systems can simply be “torn down” and replaced with new ones. This is because almost the entire functionality of modern production systems is based on software and appropriate specific interfaces; these functionalities have been developed at enormous material and engineering expense.

A first conclusion is therefore:

In order to drive forward digitalisation with as little effort as possible and to cope with the growing amounts of data associated with it, machine and plant manufacturers must be able to continue using existing data structures and interfaces!

In line with the data-oil analogy, proven and sufficiently functional “pipeline structures” must continue to be used and expanded with new “pipelines". This enables companies to improve their own competitiveness and gain new market share in their own segment or in other segments of production technology. To put it in terms of control technology for industrial systems: an OEM in mechanical engineering needs its proven field buses and interfaces for evolutionary digitalisation. At the same time, suitable physical interfaces are advantageous for the expansion of new systems and services in the edge area and for the most seamless possible connection to the world of “big data.” If you master both disciplines, you are optimally equipped to cope with the growing and, in some cases, still unknown future requirements of machine users.

Requirements for developments in digitalisation

The trend-setting requirements for developments related to digitalisation, which are outlined in the following section, are based on the experience of the HARTING Technology Group. The company provides solutions for all types of data interfaces for modern drive, control, HMI, and communication technology in mechanical engineering production systems.

HARTING is also a pioneer in many groundbreaking developments for power and signal transmission in industrial environments. In the field of Industrial Ethernet, HARTING is playing a key role in shaping various standards at the physical layer: for example, it is actively involved in solutions for SPE (Single Pair Ethernet) technology.

Decades of experience in the field of interfaces for factory automation, combined with the expertise of a trendsetter in the latest data transmission technologies (extending into the world of big data), enable HARTING to always find the optimal solution on the physical layer for every specific interface design. With the help of the right interfaces, OEMs can decisively advance the migration to digitalisation that is so important to them. In doing so, each solution must remain uncompromisingly leading in terms of the respective application with its mechanical, environmental, and EMC conditions and other requirements.

“What is the simplest and most effective way to design the interfaces for data transmission in production systems – at all conceivable levels of the factory and right up to the ‘cloud’?” This question often causes headaches in the R&D and engineering departments of machine manufacturers who want to gradually develop individual specific aspects of digitalisation in their projects.

The requirements that must be met are as follows:

All types of data interfaces should be implementable, both tried-and-tested and current innovations.

The range of interfaces must be scalable, meaning that the same interface type can be designed in the required standard version, IP protection class, or for the required environmental conditions (EMC, resistance to dirt, UV radiation, mechanical stresses such as shock and vibration, and compliance with hygiene requirements).

It must be possible to use reliable and standard-compliant interfaces for transitions between locations or sections.

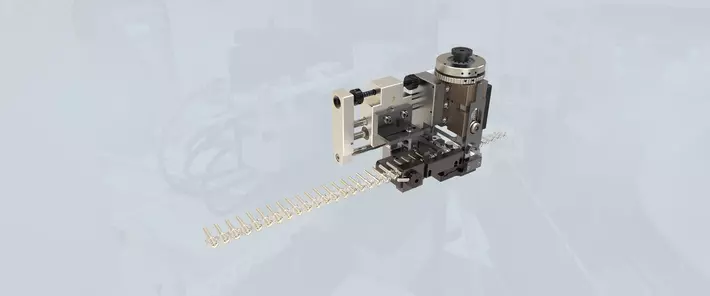

There must be product variants designed for different manufacturing and assembly processes at the OEM, e.g., for tool-free assembly if flexibility is required, or for automatic assembly if higher quantities are to be manufactured with high process reliability.

The data interfaces must be combinable with each other and can be placed with other signal and power interfaces in a housing or even together in an insulating body to save space and costs and simplify processes.

The approach outlined above allows developers and project managers to concentrate on the tasks that are central to their respective applications during the design phase – without having to spend time on the “peripheral criteria” of interfaces. At the same time, they can be sure that there is a suitable interface for every expansion stage of a machine module or data transmission link. The corresponding solutions are both cost- and function-optimized as well as scalable. Cost-efficient, technically simple expansion of services and system enhancements at all levels of factory automation and beyond can be implemented at any time, even retroactively, by the machine user.

References

T-Systems: Driving digitalisation forward now (t-systems.com)

HMS: "The aim is to generate added value from the data." (industry-of-things.de)

HARTING: Smart without damage? - INDUSTRY GUIDE 2020/2021 - NEW BUSINESS Guides

Jakob Dueck

Position: Industry Segment Manager Machinery

- Department: Industry Segment Management

- Company: HARTING Technology Group