Developments in electronic components have enabled an enormous consolidation of functions. On the one hand, this technological advance makes it easier to modularise and scale machines. On the other hand, it requires thinking in terms of ever smaller and more elementary functions, and the initial effort involved in developing the systems is growing. Despite these sometimes negative implications, the advantages of customer-oriented customisation outweigh the disadvantages. This is because the appropriate overall arrangement of sensors, actuators and other components, as well as the linking of the corresponding functions, are the absolute domain of OEMs.

Standards for individualists, or: What suits my machines?

Robot manufacturer KUKA has formulated a conclusive answer: "The key [to mass customisation] lies in a high degree of standardisation and automation, which at the same time leaves room for variations in customer-relevant product features. The concept of modularisation, which offers customers individual product configuration ... is also a cost-effective way of fulfilling individual customer requirements ..." [1] Individualisation, as it is currently being pursued, is not least one of the core aspects of Industry 4.0.

Interfaces are an important part of modularisation. But do they always have to follow certain standards? The increasing automation and modularisation of production systems bring technical and economic advantages for OEMs and end users. Interfaces are playing an increasingly decisive role in this. The experience of HARTING's customers clearly shows that it is important to differentiate, because in some areas standardised interfaces are more advantageous, while in others "customised" interfaces are better!

In order for OEMs to determine the right degree of customisation for their machines and to reconcile the sometimes conflicting requirements throughout the life cycle, it is helpful to think in terms of different "clusters" or function groups.

Function groups

Advice for customised interfaces

HARTING's analysis of customer applications has resulted in the following recommendations for customised interfaces:

In general, it makes sense to use customised interfaces for functional groups that represent a large part of the OEM's core competence.

Customer-specific interfaces are most commonly used for modules that are developed or manufactured directly by the respective manufacturer.

Standardised interfaces are usually used for sensors and actuators. However, innovators are certainly trying to set themselves apart from the market environment by using specifically tailored interfaces.

When it comes to data interfaces, mechanical engineering manufacturers rely entirely on standardised solutions. As data transmission technologies are undergoing enormous change, these are largely determined by the suppliers of the control components. The recommendation to OEMs here is:

They should follow the latest standards in control technology to ensure the desired modularity and scalability.

Beyond the machine edge, interfaces should always be state of the art. This will give OEMs an optimally designed system. It will also ensure that they are well equipped for the future expansion of services based on digital services.

For other function groups, the advantages and disadvantages of customised interfaces should be systematically weighed up. The most important reasons for non-standardised interfaces:

There are requirements from end users who want to consciously differentiate themselves from individual suppliers or focus on them.

Differentiation from competitors through data-based business models such as after-sales, service and similar services.

Consciously equipping modules with specific interfaces in order to set oneself apart from the competition. OEMs who see themselves as technology leaders in particular make use of these options.

Use of sensors/actuators or combinations thereof that have been developed according to OEM specifications: Here, too, the protection of one's own know-how is the strongest motive for using customised interfaces.

Customisation options from HARTING

What customisation options does HARTING offer to implement customer-specific interfaces? Ranked by degree of customisation (ascending), these are:

The contact inserts can be combined with different housing types according to the modular principle. This results in easy scalability for the IP protection class, EMC protection or even the installation situation;

Cable entries and printing on enclosures can be freely configured and ordered to customer specifications using online configurators.

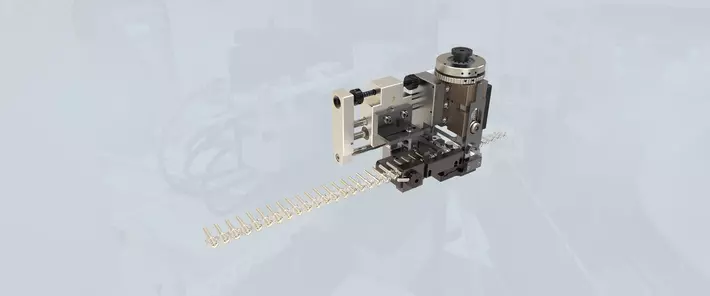

Assembly with contacts with different properties: this allows contact inserts to be designed to customer specifications.

Many contact inserts can be fitted with coding pins instead of contacts at individual locations.

Pin and socket combinations can be used for coding instead of fastening screws.

For data transmission, sections can be designed that are precisely tailored to the end user's environment; for this purpose, standardised preLink® contact blocks are used to create suitable connector types for different ends of the data lines in the required protection classes.

In modular connector systems, electrical contact inserts can be combined with other media such as pneumatics or fibre optics. The large number of available modules allows the creation of unique interfaces;

Products specified by the customer and assembled and tested by HARTING at the factory – from connector sets to individual cable assemblies.

At the highest level, interfaces are developed according to individual customer requirements – with the aim of meeting even the most unusual requests from customers in the mechanical and plant engineering sector.

References

Piller, F. T.; Stotko, C. M. (HRSG.): Mass Customization und Kundenintegration. Düsseldorf: Symposion 2003.

Jakob Dueck

Position: Industry Segment Manager Machinery

- Department: Industry Segment Management

- Company: HARTING Technology Group