Reliable, Sustainable Manufacturing Machinery Through Innovation Partnership

Throughout their 15-year partnership, Husky Technologies and HARTING have engineered high-performance, space-saving manufacturing machinery with reduced dependency on natural resources.

Industrial manufacturing is turning to more energy-efficient machinery, without sacrificing reliability and production output. Husky Technologies and HARTING both have pioneering and innovative DNA, so collaboration is a natural fit.

Together, the two companies have demonstrated the power of co-engineering and innovation between two global manufacturing leaders.

The best innovations don’t come from a single person or company; they come from collaborative efforts that combine specialized areas of ingenuity. Our companies are well-established leaders in our respective spaces, and because of our shared quest for continued inventiveness, our companies continue to lead in creating forward-thinking products.

Brad Selleck

CEO

The Path of Sustainable Molding

With its focus on finding ways to meet the world’s sustainability goals, Husky has become the go-to manufacturer for high-performance systems for packaging, medical, and consumer goods. One example is their

“We see it as our role to lead the message globally with our customers [that] we’re going to make equipment that is the lowest carbon footprint material,” says Husky CEO, Brad Selleck.

“That’s why we’ve designed our new HyPET®6e to use 100% recycled content,” he says. “Our focus is around that sustainable and circular economy and how to make sure that we’re designing all our equipment to … reduce the overall impact to the environment while minimizing natural resources.”

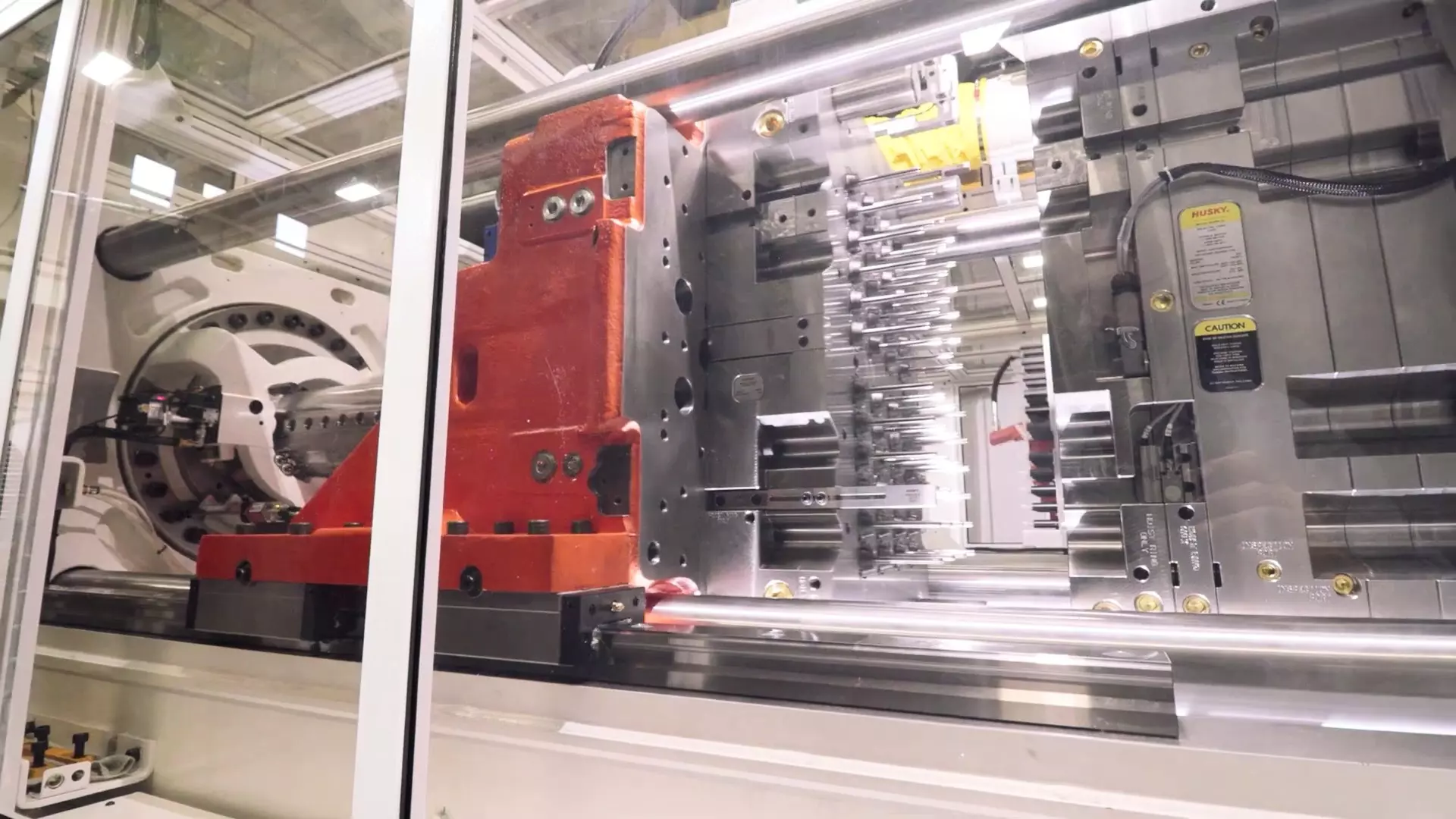

To meet these goals, Husky leverages HARTING custom cable assembly kits for quick and easy installation. HARTING’s rugged connectors and cordsets are used for power, signal, and temperature readings to ensure maximum efficiency. Their reliability also helps to extend the life of Husky machines, maximize uptime, and reduce maintenance time.

“HARTING and Husky are committed to providing innovative, sustainable technology, and our long-standing partnership emphasizes how collaborative efforts lead to better results,” adds Selleck.

Husky's customers expect durable, long-lasting machinery for high-volume production. HARTING's rugged connectors help them meet and exceed those high expectations.

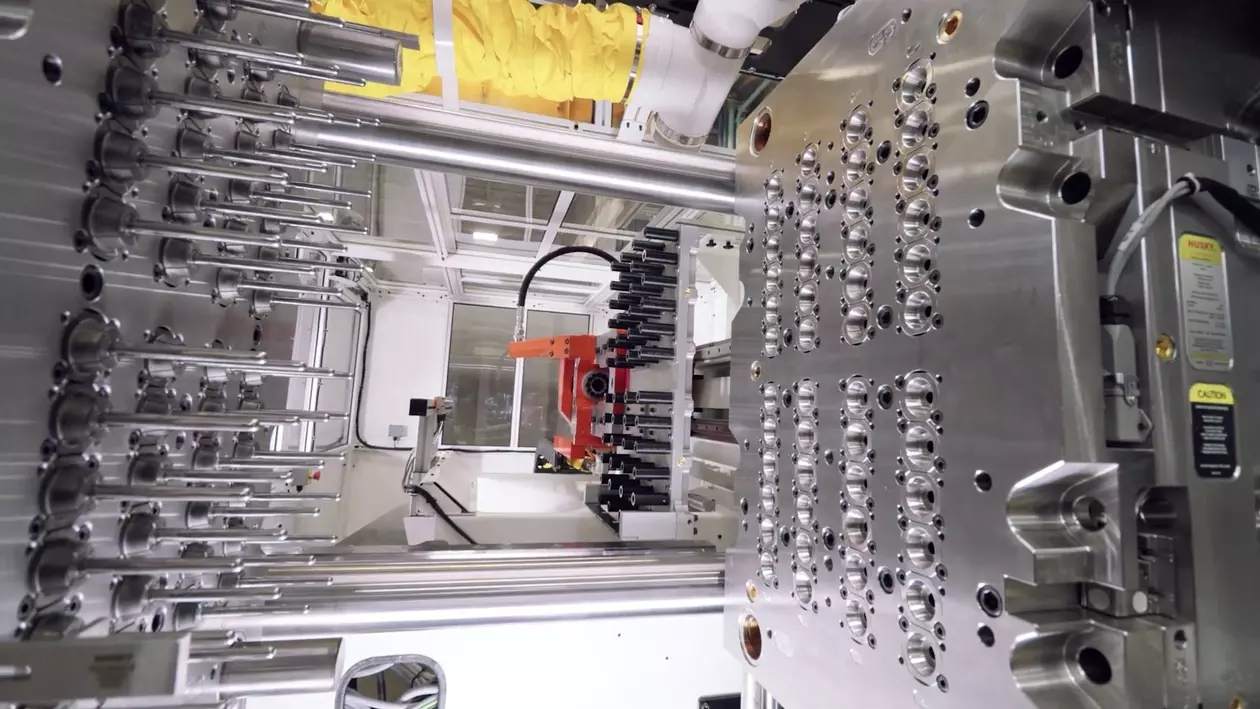

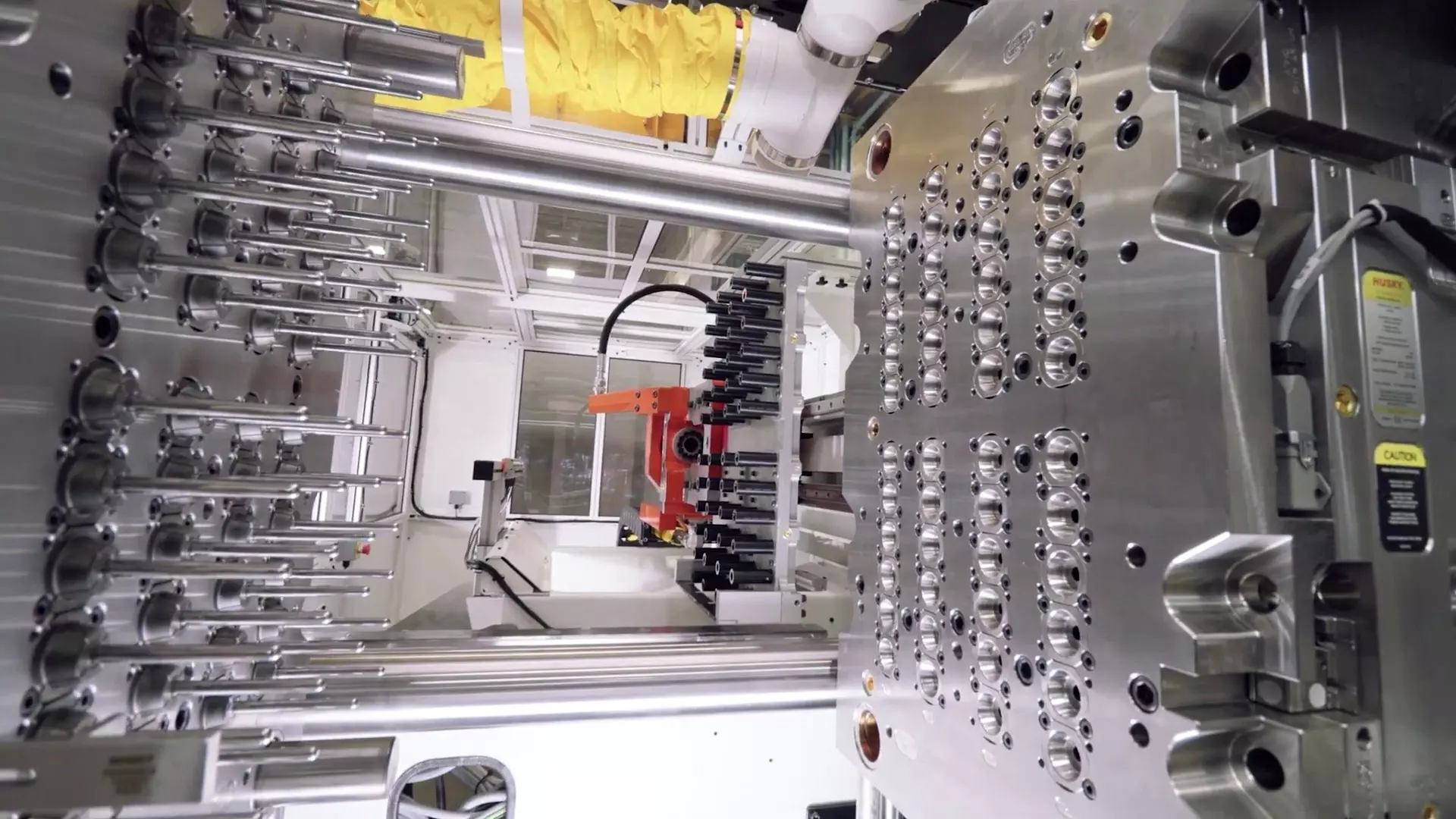

Impressions from the video

Overcoming Challenges through Innovation

Built into

“Innovation is very important for Husky,” Roman Pirog, Vice President, Innovation and Sustainability. “Husky is a technology company, and we actually keep a cadence of 18 to 24 months on innovating our products to keep our customers always in the lead.”

Real-Time Monitoring for Optimized Machinery

All of their newer systems, including the

“As we monitor and detect that something is not [operating at optimal performance], we call [the customer],” explains Pirog. “Uptime is [vital] for our customers; they require reliability and performance from our systems.”

More Performance in Less Footprint

The innovation teams at Husky often work with their HARTING counterparts to find inventive solutions to common challenges. Increasing output in less physical space is a growing puzzle for many manufacturers.

“Space constraints have become a challenge in the last few years,” says Pirog. “With smaller format connectors, HARTING solutions have made us manageable in terms of finding space for our product and making it work.”

Future-Proof Designs

A consequence of so much industrial innovation is that facilities evolve over time. Husky has found that HARTING’s connectors, especially its Han® Series, allows manufacturers to easily and quickly modify their plant floors without risking connectivity issues.

“Where HARTING assists us is that we have customers that do many tool changes and require equipment for fast-changeover and not having to troubleshoot connections is important,” says Pirog. “That’s where reliable connectivity is important.”

Setting the Standard for Controllers

Husky’s Industry 4.0-ready

Husky relies on HARTING's rugged connectors, like its Han® series, for secure and reliable connectivity.

Customer benefits at a glance:

Rapid Innovation Cycle Support

HARTING's solutions and co-engineering collaboration teams are designed to meet Husky's rapid innovation cycle of 18-24 months, enabling Husky to quickly develop and deploy new systems.Improved Productivity & Efficiency

With increased uptime and reduced energy consumption, Husky's customers boost productivity and reduce operations costs.Tailored Sustainable Solutions

HARTING develops customized, sustainable solutions that minimize environmental impact and meet the environmental-impact goals of Husky and their customers.Space-Saving Solutions

HARTING's compact connectors help Husky overcome space constraints, making it manageable to find space for their products and ensure seamless operation.

Our equipment moves hard and fast and at very fast speeds, so every millisecond matters. We need partners that value innovation and sustainability the way that Husky does.

Brad Selleck

CEO