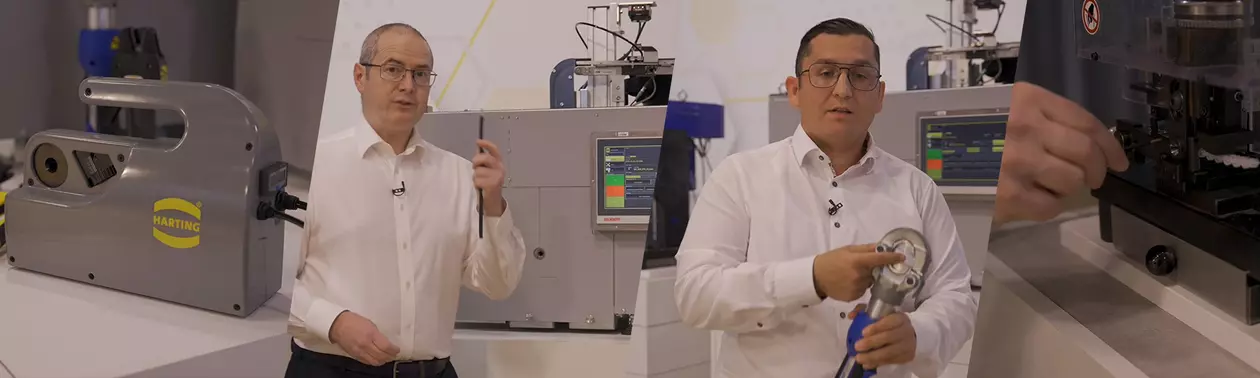

Web-Seminar | Tools to accelerate the setup of energy infrastructures

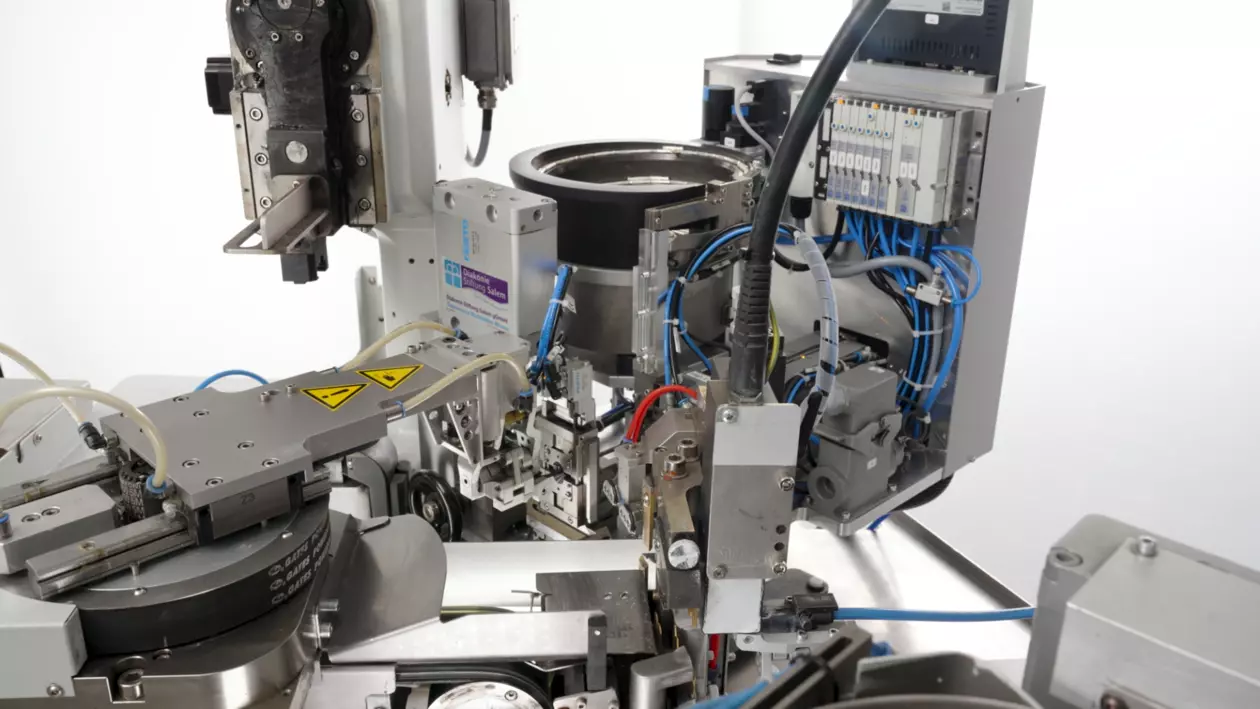

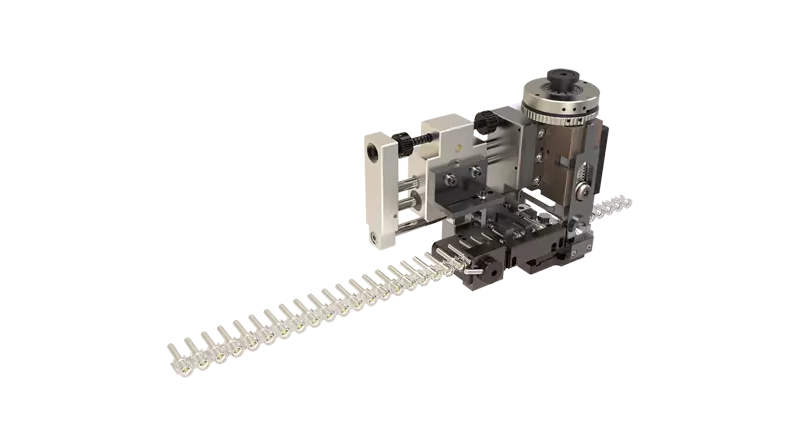

HARTING's tool portfolio ranges from simple assembly and disassembly tools, manual and semi-automatic hand tools to fully automated machines. This enables you to carry out reliable installation and maintenance - for optimum results in every application.