Green energy through scaling up hydrogen fuel cells

Sustainable power now. That is GeoPura's mission. At the forefront of the clean energy revolution, GeoPura is tackling one of the greatest challenges of our time: independence from fossil fuels.

Based in the United Kingdom, GeoPura provides clean, reliable hydrogen energy for various industries to replace diesel generators, supplement the electricity grid, reduce emissions and ensure uninterrupted power supply even in the most demanding environments.

By integrating green hydrogen production, hydrogen storage and hydrogen fuel cell technology, GeoPura is creating a resilient hydrogen ecosystem that delivers low-carbon energy where and when it is needed. HARTING's connectivity and cabling solutions are helping to scale up.

Renewable energy on demand

At the forefront of the energy transition,

GeoPura’s

The HPU2 offers efficient, robust, and safe power distribution, helping industries reduce their reliance on fossil fuels. Whether supporting grid resilience or powering remote locations, HPU2 delivers a future of sustainable, emissions-free electricity.

GeoPura's hydrogen power unit HPU2

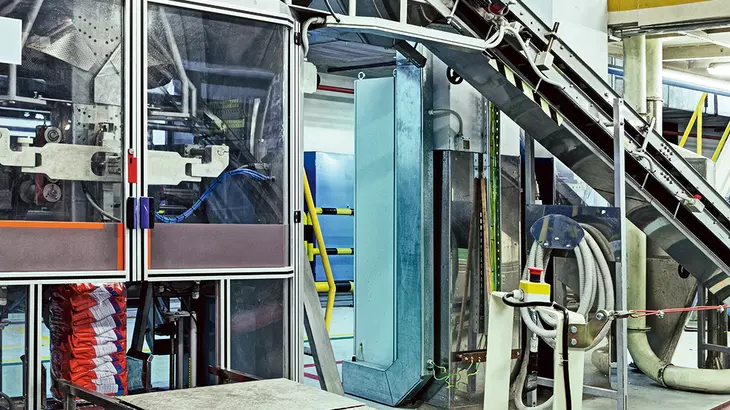

Impressions from the video

HPUs manufactured in collaboration with Siemens Energy

The hydrogen transition is well underway, but strong partnerships are needed to drive it forward. GeoPura's strategic partnership with

Since 2019, the Hydrogen Power Units (

A key challenge is scaling up this innovative solution to meet the growing global demand for clean energy. The partnership between GeoPura and HARTING has advanced manufacturing of the fuel cell generators in the UK. By working closely together, the companies have been able to accelerate the production of hydrogen power systems and use the available space as efficiently as possible. The result is outstanding.

Hydrogen power units mass-manufactured in collaboration with Siemens Energy

Pre-assembled connectors speed up scaling while reducing space requirements

The partnership between GeoPura and HARTING is a real success story based on a shared vision of the

Engineers from both companies discussed various options for accelerating the production of the HPUs. One of these proved particularly advantageous for scaling: the use of pre-assembled cable harnesses with rear mounting functionality.

Normally, cable harnesses and connector parts must be inserted from the inside of the control cabinet into a housing attached to the inside wall of the control cabinet. This can be quite a complex challenge. The rear mounting option for industrial connectors offers valuable time savings for equipment using the

For installation, both ends of the cable harnesses can be rear-mounted from the inside of the switch cabinet into the bulkhead-mounted housing. HARTING supplies them as pre-assembled and tested cable assemblies. This allows the work to be divided up, further increasing efficiency and thus productivity.

Another key to succeess is the use of HARTING’s

Cable harnesses and connectors with the rear mounting option speed-up green hydrogen scaling

Customer benefits at a glance:

Accelerated scaling of HPUs thanks to pre-assembled and tested cables with the rear mounting connector option

Reduction of manufacturing cost by an optimised division of labour

Higher I/O density enabled by using the Domino modules to reduce the connectivity footprint by up to 50%

Future-proof connections offering maximum flexibility as scalable to the respective need

Joint development on new solutions meeting future challenges, e.g. for the ATEX Zone 2

A key benefit of HARTING is using the rear mounting cable assemblies. which we are using in all our control panels within HPU2. And HARTING offers that in pre-assembled connectors, which allows to manufacture extremely quickly. The other thing is I/O. So I/O density is really important to us, and we have been able to cram those in using the Domino modules, which has been really helpful.

Jeremy Stratford

Head of Electrical Engineering | GeoPura