Compact, robust connectivity solutions for semiconductor manufacturing equipment

Why is footprint such an important issue for semiconductor tool and equipment designers?

Fabs - the factories where semiconductor chips are made - are expensive to build, now exceeding $10B for those that make the most advanced chips. And inside the fab, cleanroom space can span 100,000m2 or more, housing thousands of manufacturing tools.

Because the cost to build a fab is so enormous and the cost to operate cleanroom space is very high, fab owners and operators prioritize uptime, reliability, and space when it comes to choosing the equipment, or tools, they use for chip manufacturing.

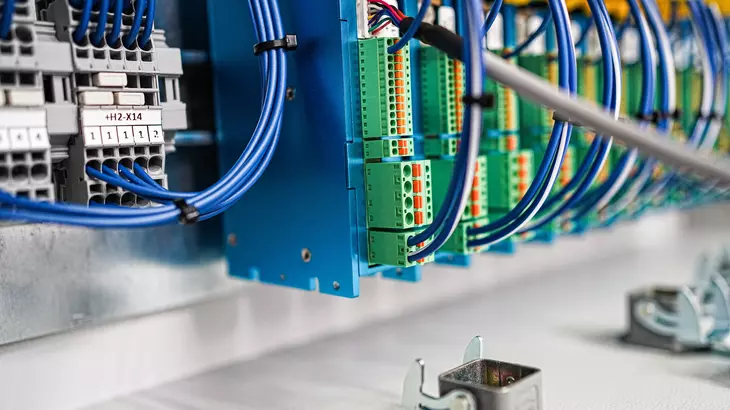

Although connectors might seem like a very small contribution to the size of a semiconductor tool, each tool can have hundreds - or even thousands - of electrical connections for power, data, and signals. And these connectors are often used with cables and wires that have a limited bend radius, special EMC requirements, or even environmental specifications such as cleanroom or vacuum compatibility. Considering the number of connectors per tool and the constraints that electrical engineers face, size and design flexibility become very important considerations when choosing connectivity solutions.

The solution: Smaller, reliable, modular connectors

Modular connectors let electrical engineers combine power, data, and signal connections into a single unit. This integration reduces the space needed for connectors and cables, providing significant design flexibility. Similarly, choosing a different type of connector that can accommodate the same power or data requirements as a “legacy” design can lead to significant space-saving and, in some cases, improved reliability and easier assembly.

For example, some customers have replaced traditional D-sub connectors with the

At the PCB level – inside the devices – connector pitches are shrinking from 2.54 mm to 1.27 mm. This miniaturization addresses the challenges of incorporating more features and facilitating higher data transfer rates by enabling more connectivity and higher pin counts within the same space. Products like

Watch to find out how the har-flex® connector can maximize PCB space

What benefits are there to co-designing or co-innovating with an OEM?

Connectors are highly customizable, and cable assemblies can be designed and manufactured exactly to a customer’s specifications. If you have a challenge with space, power density, shielding, or any sort of environmental concern, the connector and cable assembly manufacturer can often come up with a custom solution that will meet your specific needs. Additionally, the manufacturer has experience in a wide range of industries, so they might have encountered a similar situation in a completely different industry and already have a solution or a foundation for how to solve that issue.

“Ease of use” isn’t a technical spec you’ll find in a catalog. But our experience in the semiconductor industry helped us understand the customer’s problem and develop a connector that was both easier to use and took up less space.

Danielle Collins

Sr. Industry Segment Manager

Optimizing connectivity for cleanrooms

A major tool manufacturer needed a rugged connector that could be plugged and unplugged easily in the cleanroom by technicians with gloved hands. The D-sub connectors they were using presented a real challenge, as the connector’s small screws were easily dropped or lost, and locking latches were difficult to handle, especially when the connectors were in hard-to-access locations.

To solve these problems, we developed the

Danielle Collins

Global Sr. Industry Segment Manager

HARTING

Our in-house expert in in the semiconductor and machinery industry, Danielle has over 25 years of experience in industrial business processes and thought leadership.