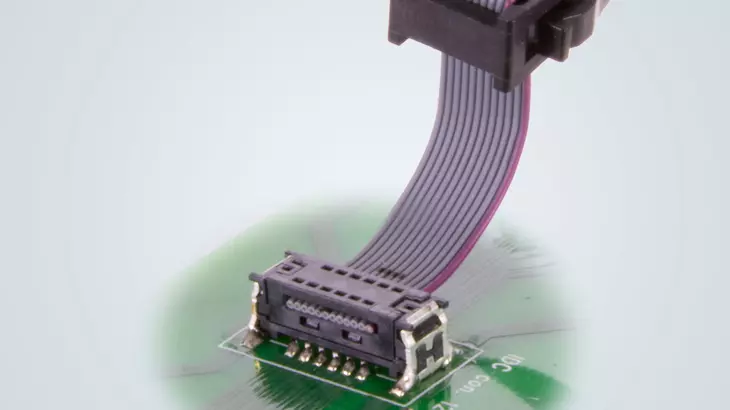

Both straight and angled versions as well as the IDC cable connectors are available in all even pole counts between 6 and 100. This is made possible by an innovative modular manufacturing concept, redefining customized versions to standard components. The use of the precisely fitting number of poles and design allows highest flexibility in device design and supports the miniaturization of devices.

har-flex®

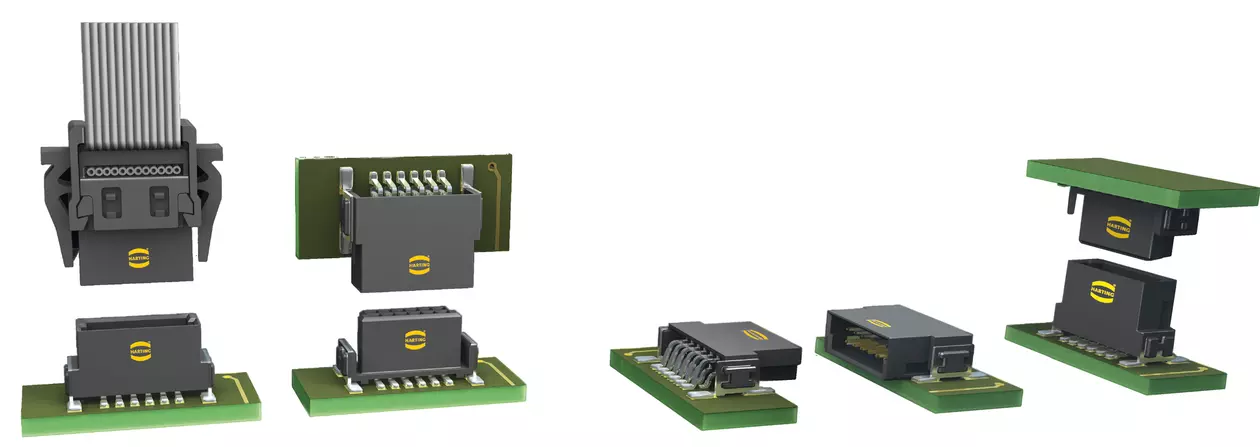

Smaller, more powerful and more robust at the same time is the credo in all areas on the way to Industry 4.0. The miniaturized design and high variability of har-flex® PCB connector provide device manufacturers with a freely scalable connection technology that enables them to meet the demands of miniaturization. Signal, Data and Power - the har-flex® PCB connectors offer a wide range of connection solutions for printed circuit boards, featuring diverse designs and pole counts.

Series highlights

Filter

Products 1125

har-flex HD-Card Edge 100p PL1 SAMPLE

har-flex str m 4.85mm 80p PL1 250pcs

har-flex Hybrid M ang 8+36 SMT PL1Sample

har-flex str F 13.65mm 12p PL1

har-flex str m 4.85mm 20p PL1

har-flex Hybrid F ang 8+36 SMT PL1Sample

har-flex str F 13.65mm 16p PL1 170pcs

har-flex str m 4.85mm 12p PL1 250pcs

har-flex str F 13.65mm 20p PL1

har-flex str m 1.75mm 26p PL1 280pcs

har-flex str m 4.85mm 20p PL1 250pcs

har-flex Hybrid M str 4+16 SMT PL1Sample

har-flex str m 4.85mm 32p PL1

har-flex str m 3.25mm 20p PL1

har-flex str m 4.85mm 12p PL1

har-flex str F 13.65mm 80p PL1

har-flex Hybrid F str 4+16 SMT PL1Sample

har-flex str m 4.85mm 80p PL1

har-flex str f 9.05mm 20p PL1

har-flex Power M ang 12P THR PL1 Sample

Discover more

Get to know har-flex®

You are readesigning your producut and now need more pits, more current, more signales and more data? But the product should not get any bigger? Our connectors from the HARTING har-flex® familiy smaller, flexible and more robust to meet your requirements.

Application example

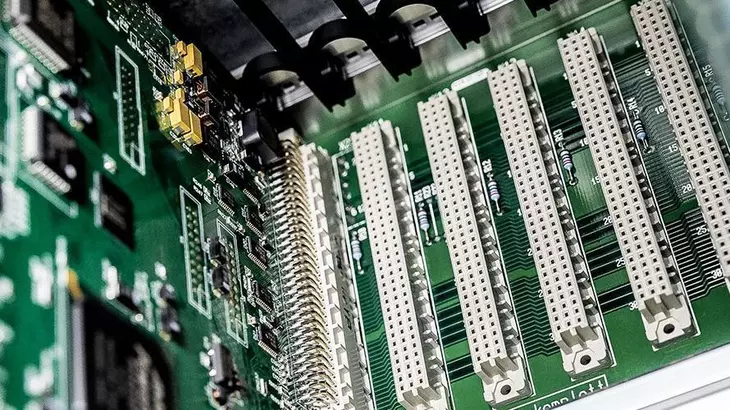

Control cabinet space is money in machine and plant construction. Depending on the requirements of the customer application and the packing density of the IOs, stringing together 50 or more IO modules is quite common. It quickly becomes clear that each millimeter saved in the width of the individual module has a significant influence on the space saved in the control cabinet.

har-flex® Power PCB connector

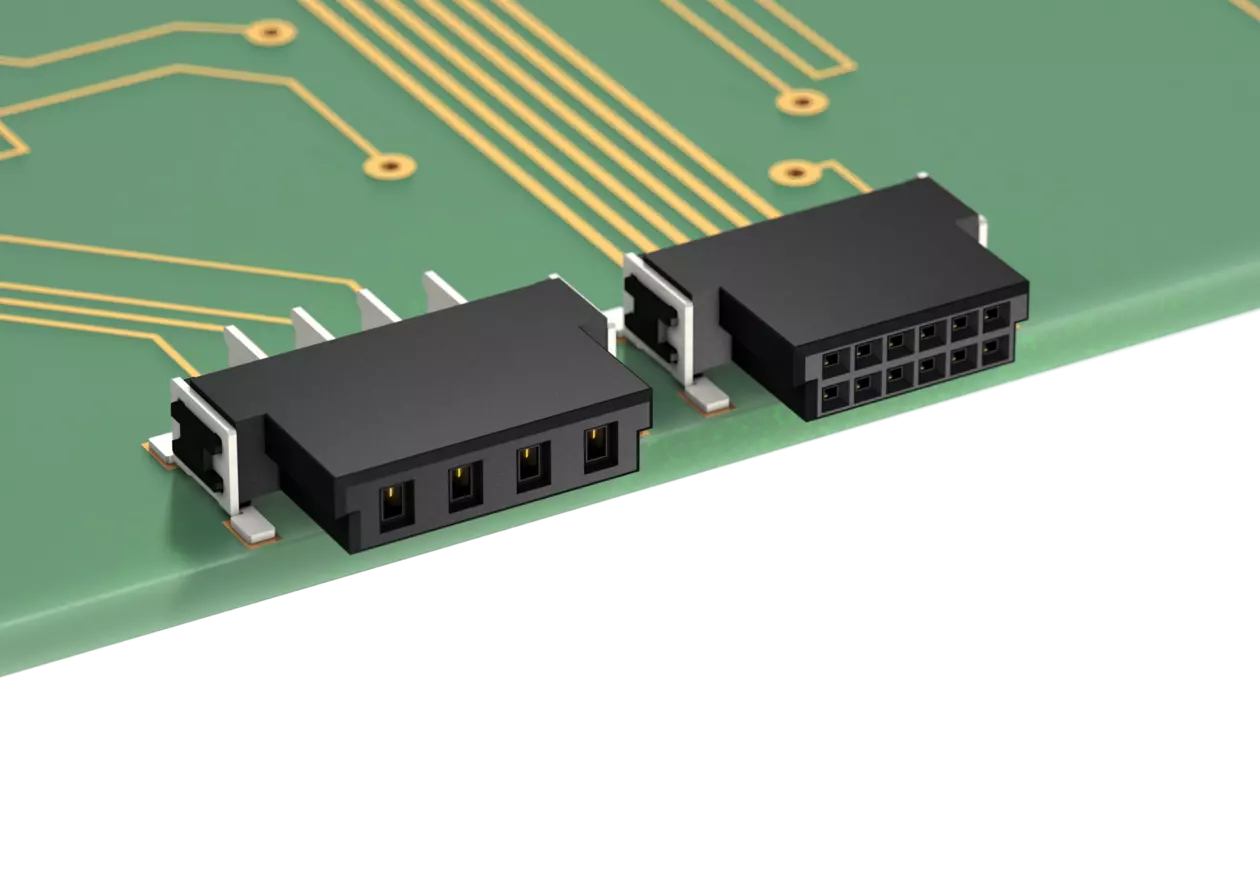

In addition to the standard har-flex® in 1.27 mm pitch, the har-flex® product family also offers connectors with 2.54 mm pitch. har-flex® Power was specifically designed for the transmission of high currents between 18 A and 29 A.

The flexible pole numbers from 2 to 12 are made possible by a modular manufacturing concept. Moreover, users can choose between SMT and THR power contact versions. har-flex® Power PCB connectors are available in straight and angled design and can be used in parallel (mezzanine) board, extender card and motherboard-to-daughtercard configurations.

Thanks to the same form factor, har-flex® Power and Signal can be used together on one PCB. This allows a strict separation of signal and power, while maintaining a coherent connector system.

har-flex® Hybrid PCB connector

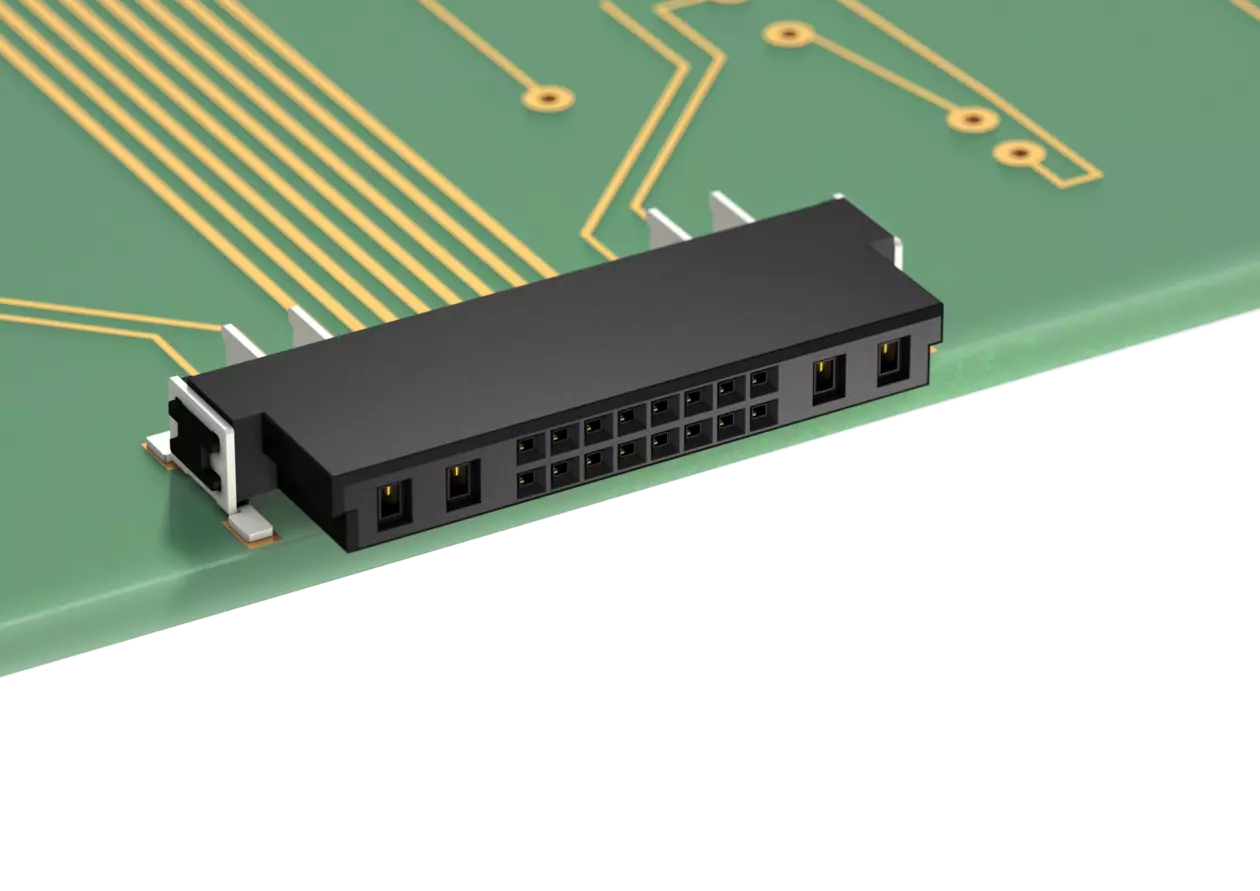

A special feature of the har-flex® PCB connector family and the modular manufacturing concept is the combination of signal and power contacts: the birth of the har-flex® Hybrid. This makes compact and versatile connection solutions possible, which are ideal for miniaturized PCB systems.

har-flex® Hybrid connectors are available in straight and angled versions and can be used in parallel (mezzanine) board, extender card and motherboard-to-daughtercard configurations.

By using hybrid connectors, space and effort can be saved on a PCB - ideal for modular IO systems and other control applications.

har-flex® Signal PCB connector

The familiar har-flex® PCB connector with the proven 1.27 mm pitch is ideal for miniaturized industrial applications. Pole numbers from 6 to 100 in steps of 2, paired with a wide variety of straight and angled designs and IDC cable connection versions result in a diverse range of possibilities. Customers can implement new and smaller systems without compromising robustness.

Even customized versions are possible on request. The trend is increasingly moving away from standardized rack solutions towards modularized devices which require miniaturized and customized PCB arrangements.

har-flex® HD - Card Edge PCB connector

The one-piece connectors of the har-flex® HD - Card Edge series with a contact pitch of 0.8 mm allow printed circuit boards with a thickness of 1.6 mm to be plugged directly.

Due to the small number of contact points, the HD-Card Edge connectors can be used in high speed applications with data rates of up to 25 Gbps. Pole numbers from 20 to 140 and optional hold-downs (SMT or THR) allow the user to adapt the connectors to their individual industrial requirements.

More solutions and resources

Knowledge

Engineering data & services

CAD data, product data manager, distributors availability, free samples & more.

Discover the HARTING Engineering Data & Services to support your project as best as possible. For each product in our digital catalogue you will find further engineering data and services:

CAD data, data sheets and type sheets

Product selectors with multiple attributes

Individually data packages

Configuration and customization

Individual notes and deratings

Free sample service