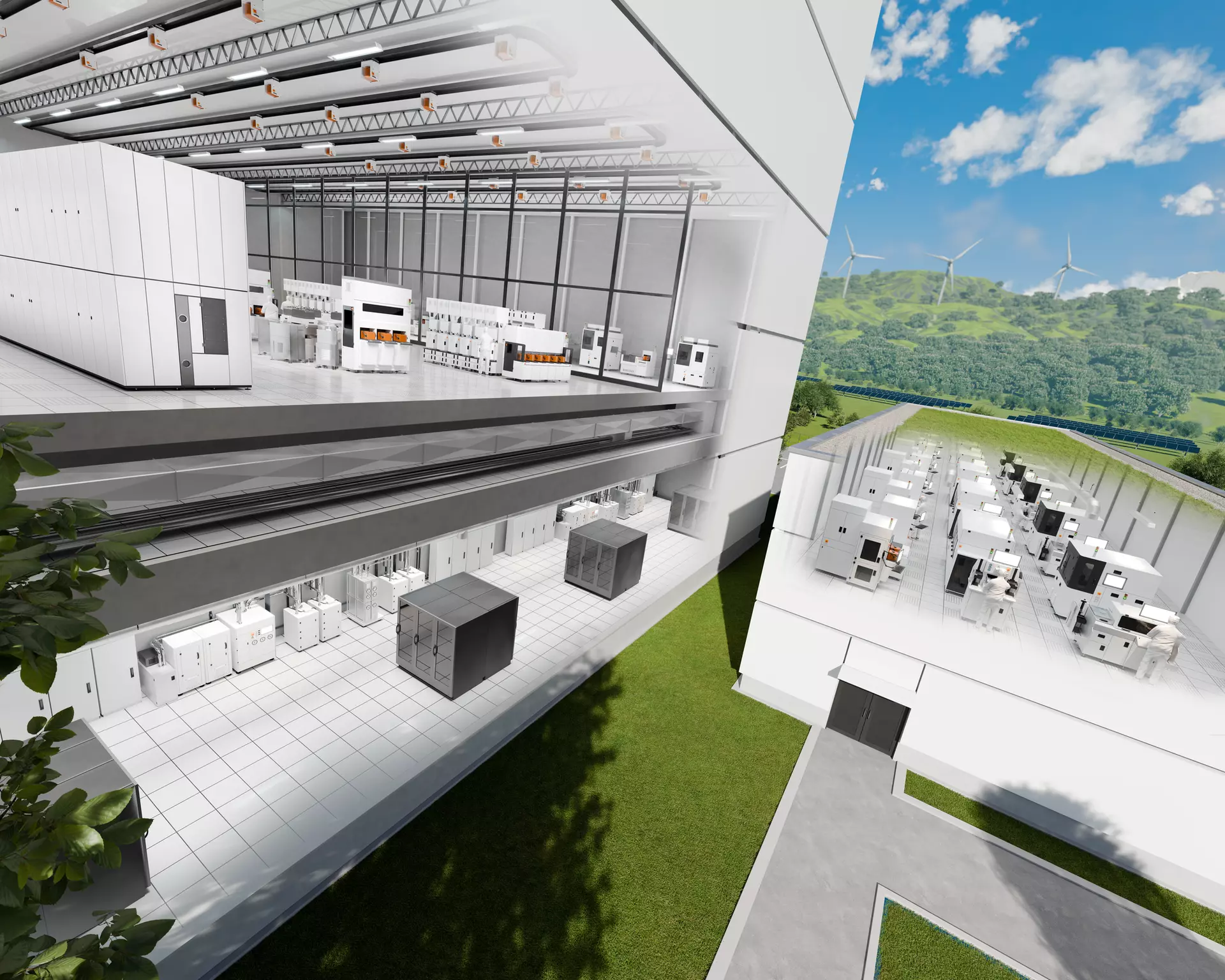

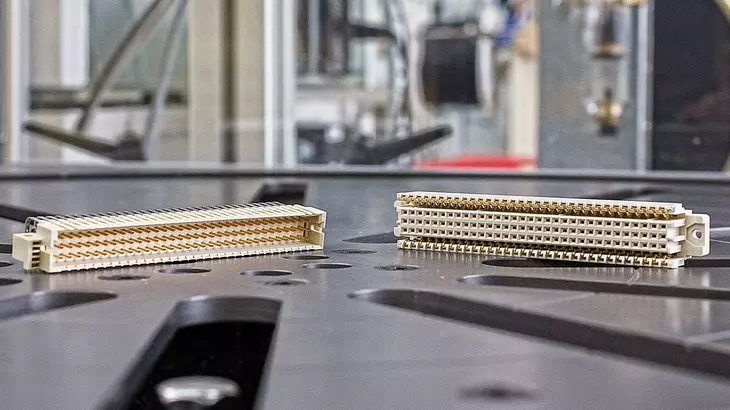

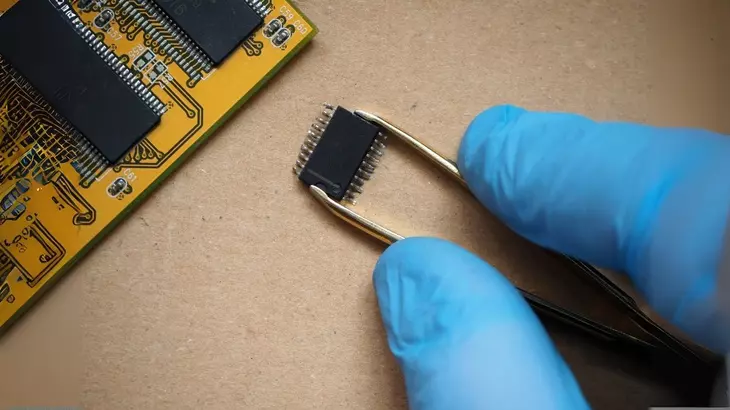

Connectivity is the backbone of semiconductor equipment design because it enables seamless communication between sensors, actuators, control systems, and data networks. Case in point: each tool can have hundreds — or even thousands — of electrical connections for power, data, and signal.

Poor connectivity can lead to signal degradation, process interruptions, and costly downtime.

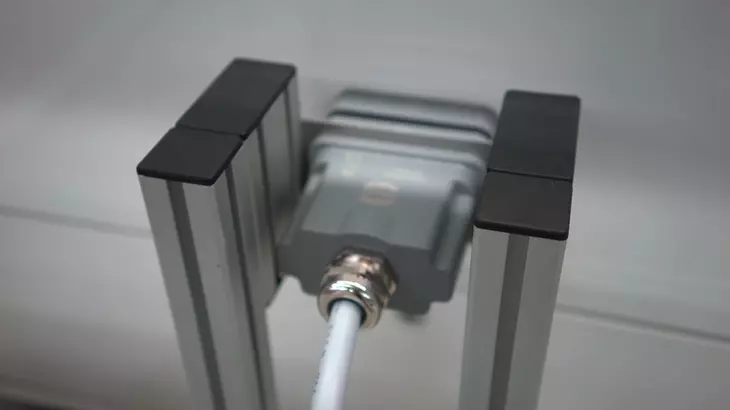

Advanced tool and equipment demands modular, scalable, and reliable connectivity solutions that support real-time monitoring, predictive maintenance, and integration with factory automation systems.

Whether it's transmitting high-speed data from inspection tools or powering robotic arms in wafer handling, robust connectivity is essential for maintaining throughput, yield, and quality across the entire manufacturing process.