HARTING offers a wide range of products that enable reliable power supply and process monitoring for electrolysers. Our HPR connector portfolio and HPTC (High Performance Transformer Connector) high current connectors ensure safe and efficient power transmission between transformers, rectifiers and electrolysis stacks. The modular design of HARTING products enables customers to design their solutions flexibly and scale production easily.

In addition, M12 circular connectors ensure a stable connection of pressure sensors, while Han® connectors enable the safe connection of switch boxes to the main control cabinet in hazardous environments.

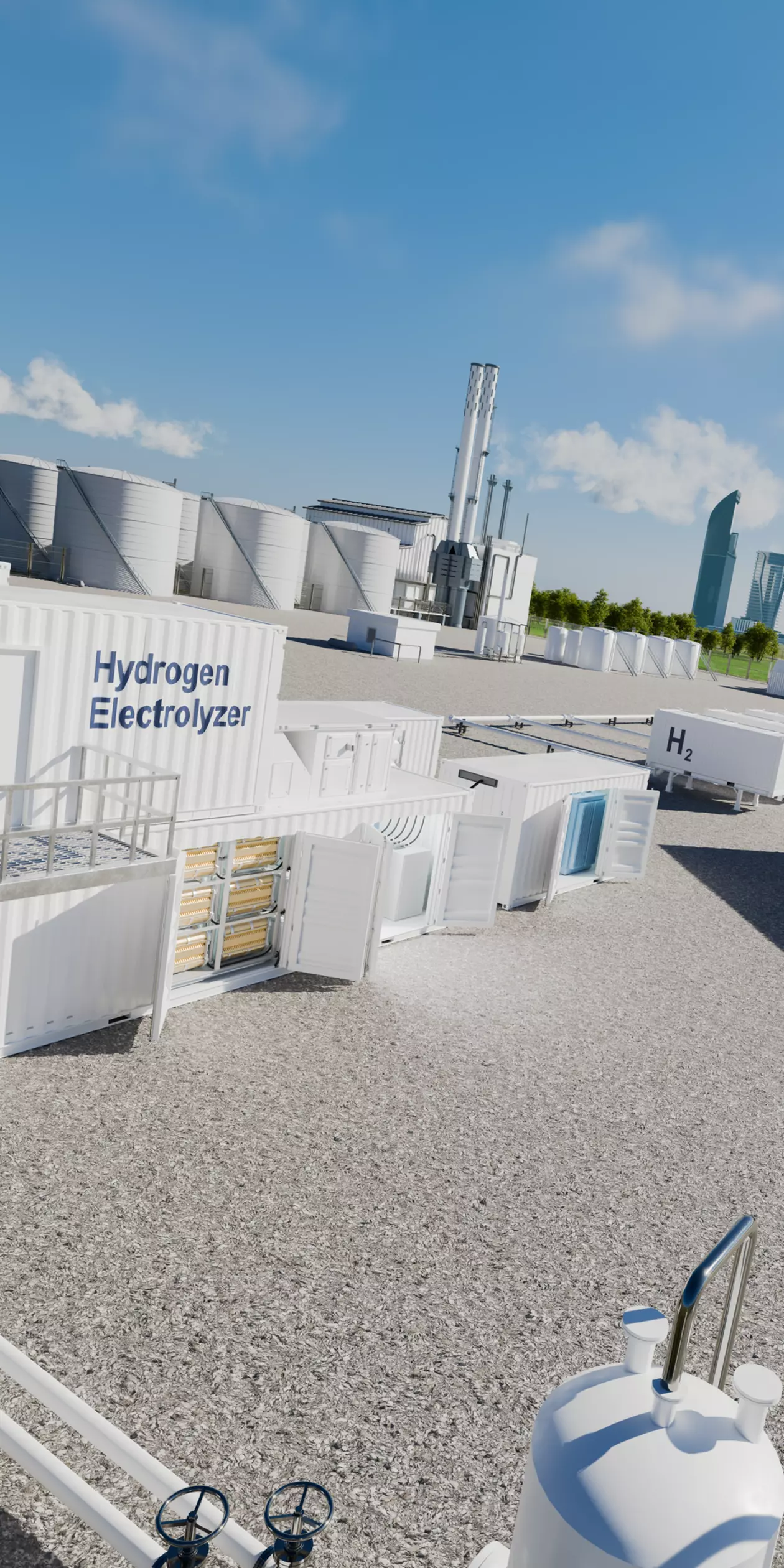

Hydrogen production

The production of hydrogen is a key step on the way to a sustainable energy future. HARTING components play a decisive role in the scaling of electrolysers. We offer connectivity solutions, that meet the specific requirements of the hydrogen production and develop customised solutions for your application.

Hydrogen can be produced in various ways, with electrolysis being one of the most common. In electrolysis, water is split into hydrogen and oxygen using an electric current. This process can be powered by renewable energy sources such as wind power, solar energy or hydropower, making it environmentally friendly and sustainable. This is known as green hydrogen.

HARTING supports this development with powerful connectivity solutions that are essential for the integration and operation of electrolysis plants. By providing the necessary technologies, we contribute to the more efficient use of hydrogen as an energy carrier and thus make a significant contribution to the All Electric Society. Our connection solutions are perfectly tailored to the modular architecture of the electrolyzer, allowing for flexible and easy scaling as well as quick installation and maintenance (Plug and Play) on-site.

Other production methods include methane vapour reforming (SMR), in which hydrogen is obtained from natural gas. Biomass gasification converts organic material into hydrogen. Technological progress is making all these production methods increasingly efficient and cost-effective.

The advantages of hydrogen technologies are manifold and offer great potential for a sustainable energy future. Some of the most important advantages are:

Hydrogen electrolyzer

This is how HARTING products and solutions help in the production of hydrogen. Discover our application possibilities here:

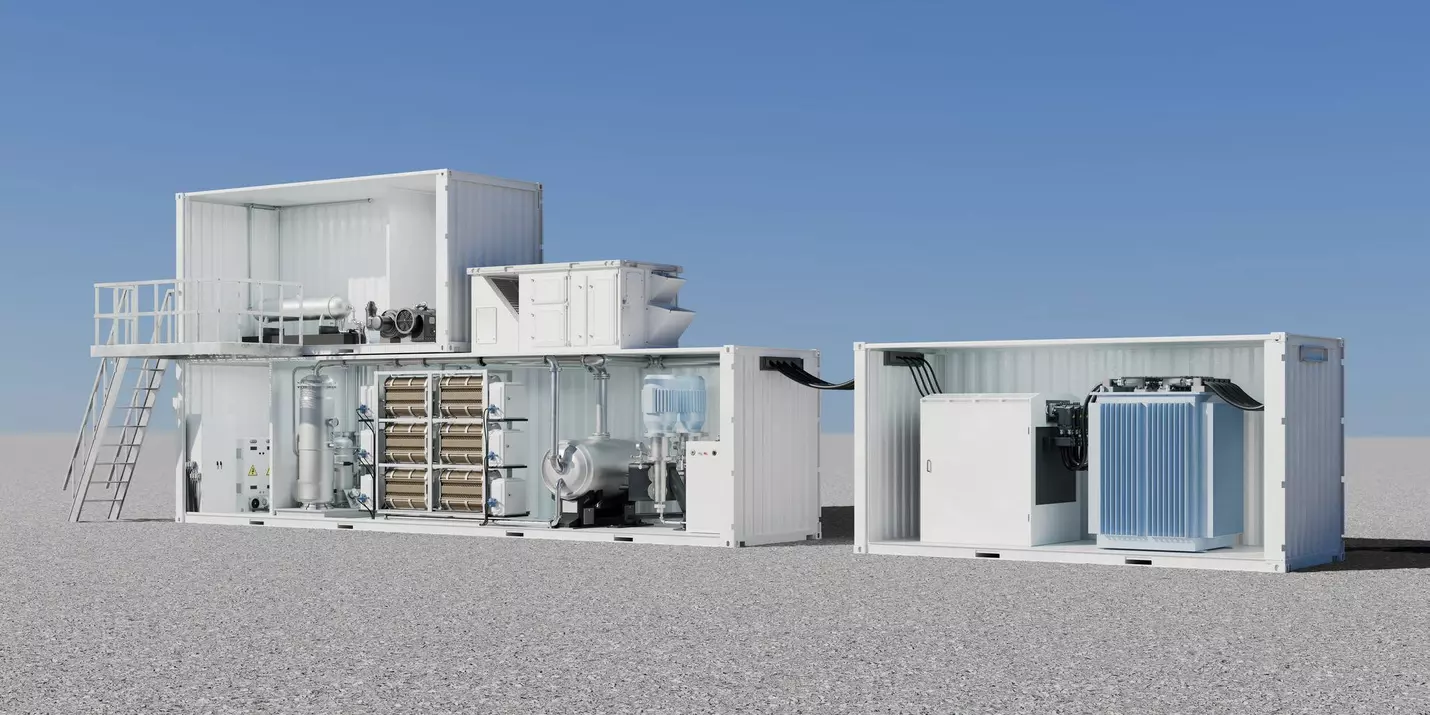

Efficient power supply for electrolysers

A precise power supply is essential for the optimal functioning of the stacks in the electrolyser, which split water into hydrogen and oxygen. HARTING supplies innovative solutions such as HPR connectors and HPTC high-current connections that ensure reliable and low-loss power transmission. These components seamlessly connect transformers and inverters to the electrolysis stacks to precisely adjust the current to the required parameters. The robust and modular design of HARTING products allows customers to flexibly customise their solutions and easily scale production. For installation, the modules are connected by simply assembling the connectors, which makes the process much easier. HARTING connectivity is ideal for industrial applications and offers maximum efficiency, durability and easy maintenance. HARTING creates the perfect basis for sustainable and economical hydrogen production.

Maximum protection against explosions

Reliable and safe connections are crucial in potentially explosive atmospheres, such as those that can occur in hydrogen production. HARTING offers different Han® connectors specifically designed for use in hazardous environments. These robust connectors connect the control boxes mounted on the electrolysis stacks to the main control cabinet. They ensure safe transmission of power and signals, even under extreme conditions. The Han® Ex connectors offer maximum protection against explosions and are therefore ideal for safe operation in potentially explosive atmospheres. With their high robustness and easy handling, they support the efficiency and safety of the entire electrolysis plant, even in the most demanding environments.

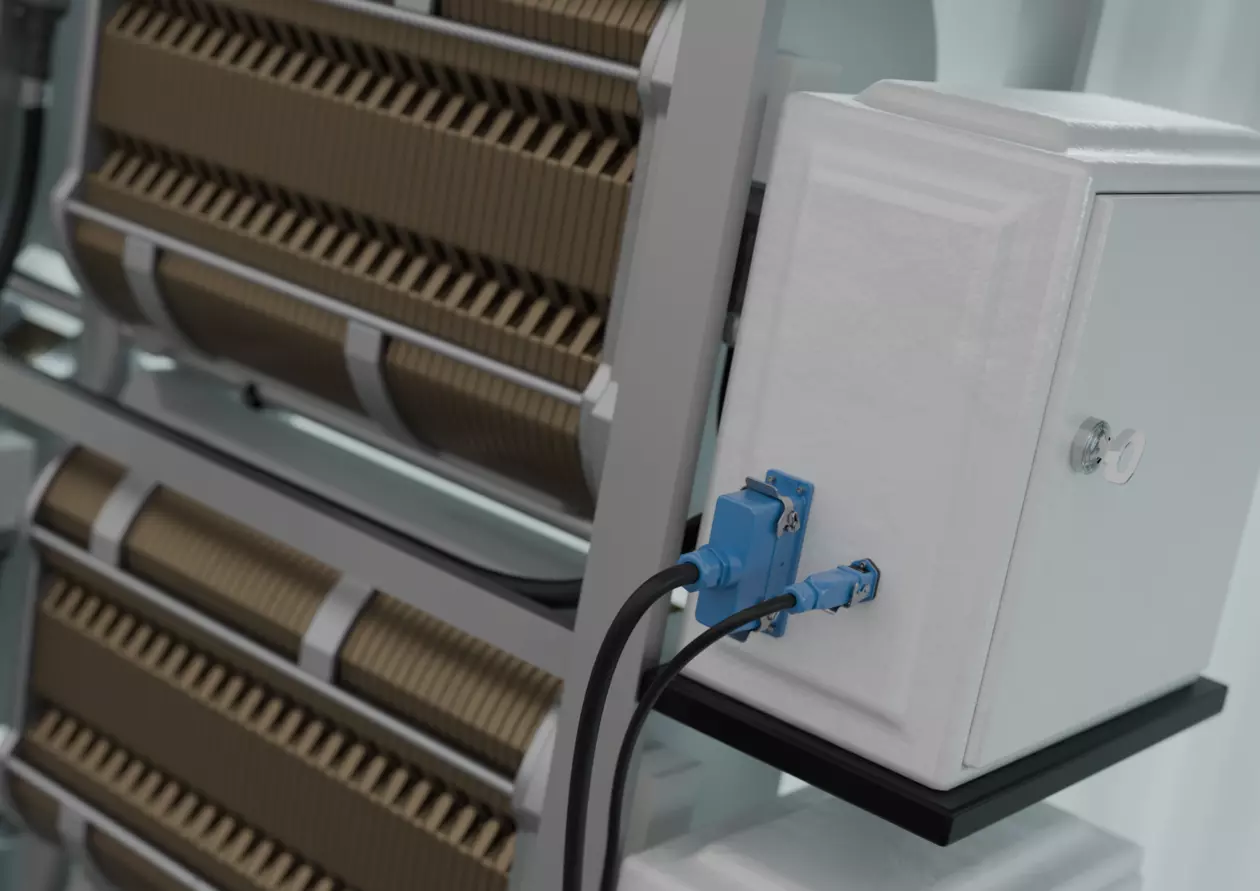

Secure connections for pressure, temperature and valve positions

Sensors play a crucial role in the electrolysis process by reliably monitoring the operating parameters of the electrolysers and ensuring safety. HARTING offers robust circular connectors for this purpose, which enable a safe and stable connection between the sensors and the control technology. The circular connectors are compact, robust and specially developed for industrial environments, making them ideal for demanding conditions such as high temperatures, humidity and mechanical loads. HARTING thus supports precise process monitoring and ensures maximum efficiency and safety in hydrogen production.

Interested? Get in touch with us!

If you are involved in the planning or manufacture of electrolysers and are looking for reliable connection solutions, please get in touch with us!

Hydrogen News

Your Contact Person

Bo Wang

Position: Industry Segment Manager

- Department: Industry Segment Management Energy

- Company: HARTING Technology Group