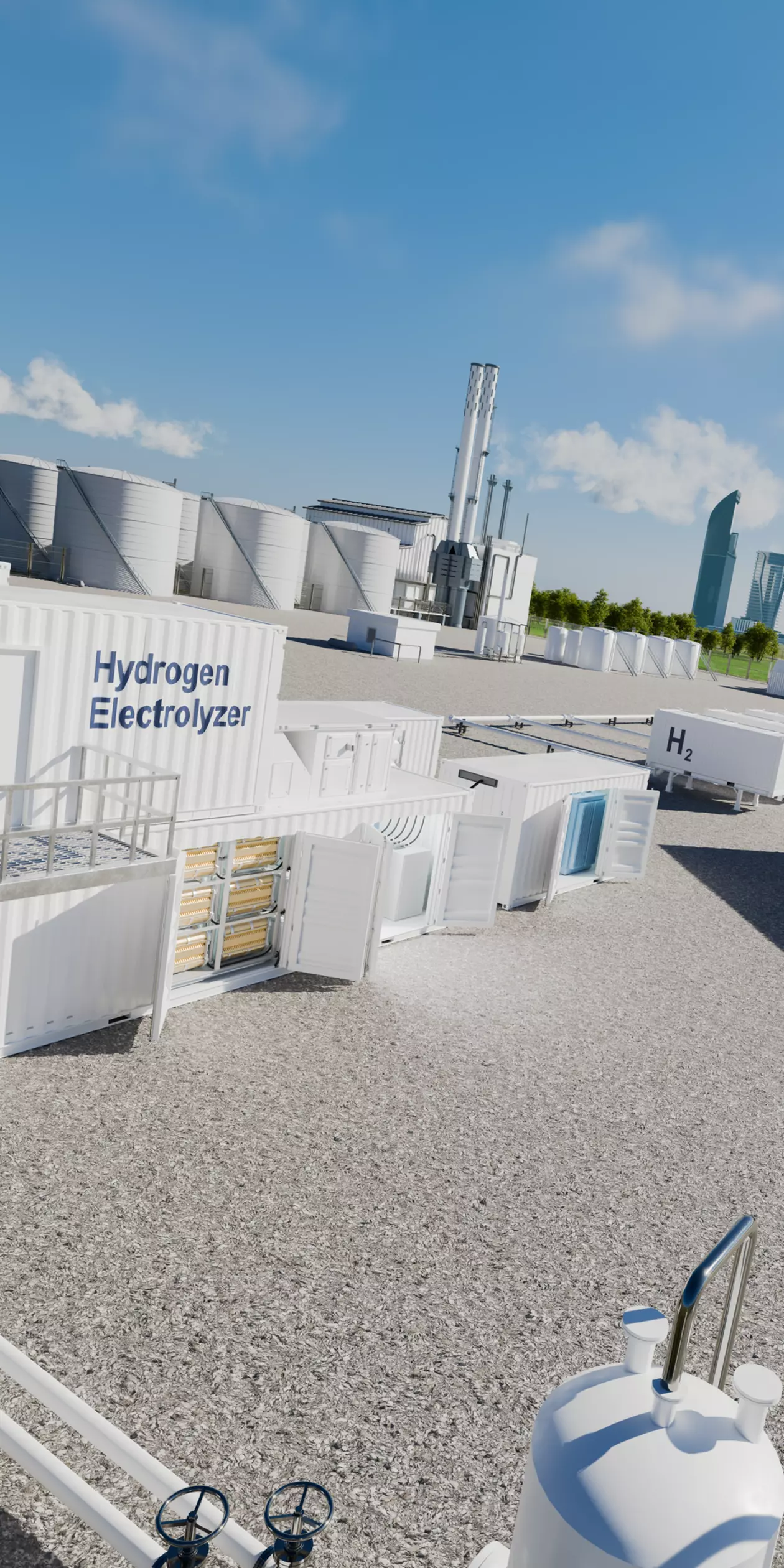

The storage of hydrogen plays a central role in the energy transition. It enables an independent energy supply by allowing hydrogen to be converted back into electricity during periods of low power generation. It also helps with the decarbonisation of industry and supports the switch to environmentally friendly drive technologies.

Hydrogen storage and transport

The transport, storage and transfer processes of hydrogen not only require reliable connection solutions, but also precise monitoring of all relevant parameters. HARTING offers customised complete solutions that can be integrated into mobile hydrogen containers to save space and fit perfectly.

There are various ways of storing hydrogen

In gaseous form in pressurised tanks or underground cavern storage facilities under high pressure

In liquid form in insulated cryogenic tanks at a temperature of -253 °C

Adsorbed in suitable solids such as carbon or certain metals (metal hydride storage)

Adsorbed in suitable liquid carrier media, e.g. oil (liquid organic hydrogen carrier)

The stored hydrogen can be transported by truck, ship or rail in various states of aggregation or as a carrier medium.

The storage of hydrogen is a key aspect of the energy transition. The aim is to make this versatile energy carrier available for a wide range of applications. Why the storage of hydrogen is so important is explained below:

Transportation and Storage Solutions

This is how HARTING products and solutions assist in the storage and transport of hydrogen. Discover our application possibilities here:

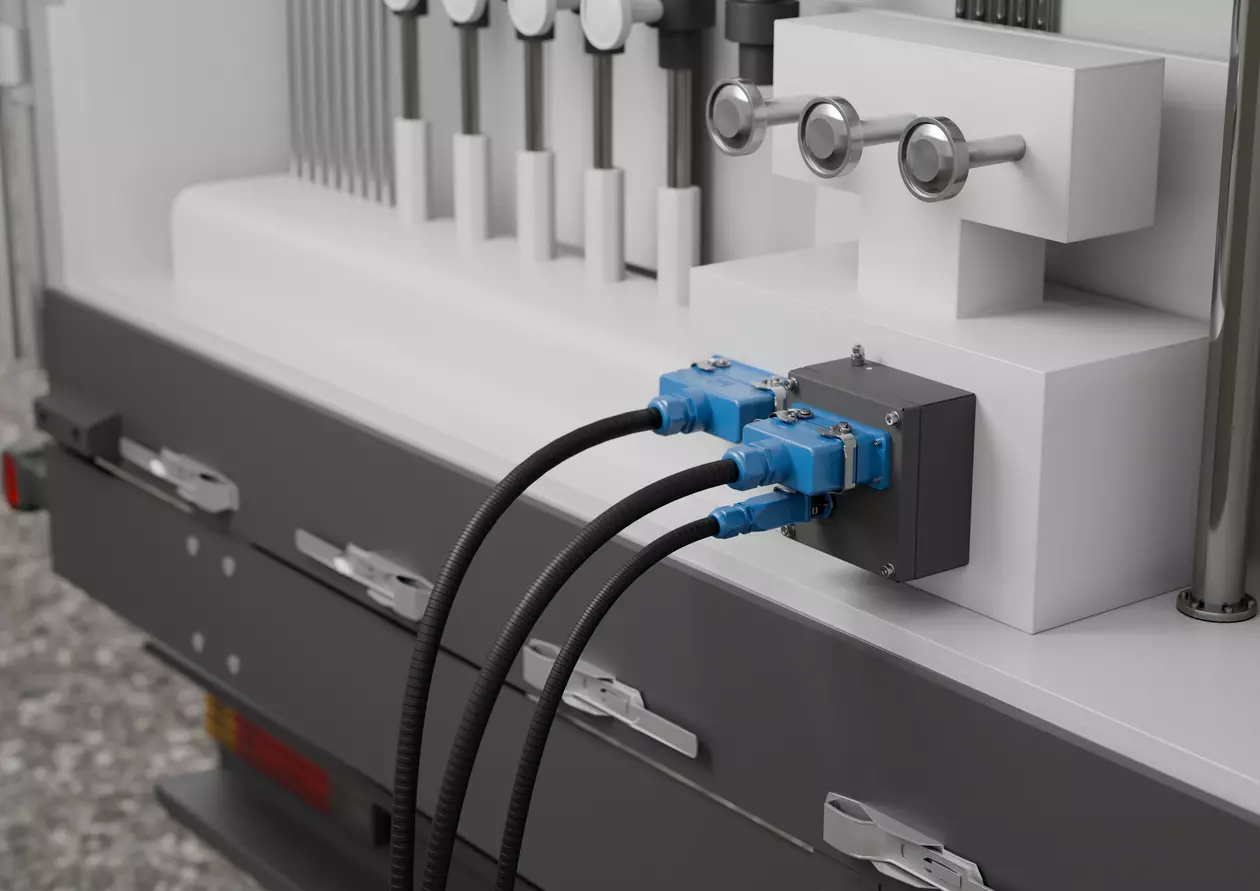

In the areas relating to the production (electrolysis), storage, distribution and filling of hydrogen, modular and individually configurable components as well as customised system solutions from HARTING are used. We specialise in providing system solutions and offer electrical distribution boxes that meet the requirements of our customers. Our system solutions are customised to ensure precise and space-saving integration. They consist of assemblies with plug connectors and connection distribution boxes. The electrical distribution boxes are ATEX-approved.

Our commitment to customization and space optimization is further exemplified by our connectivity boxes, which are available in both stainless steel (grades V2A and V4A) and powder-coated steel. These boxes are engineered to provide robust and space-efficient connectivity options that seamlessly integrate into your existing infrastructure.

Understanding the importance of safety, we also supply intrinsically safe Ex-i solutions suitable for all types of signals. This ensures that our systems can be deployed in environments where safety is of paramount concern. Additionally, we offer the capability for valve control through pneumatic connections, adding another layer of precision and reliability to our solutions.

Interested? Get in touch with us!

If you are involved in the planning or manufacture of electrolysers and are looking for reliable connection solutions, please get in touch with us!

Hydrogen News

Your Contact Person

Bo Wang

Position: Industry Segment Manager

- Department: Industry Segment Management Energy

- Company: HARTING Technology Group