Modularity in production engineering: How granular can it be?

The principle of modularity can best be explained using Lego bricks as an example: a few basic bricks and defined connecting elements can be used to create countless objects with different functions. This approach has also become established in industry for products with a higher degree of complexity and variability. In control and drive technology, systems such as PLCs, IPCs, HMIs and drive components can be assembled from individual "slices" or several remote I/O blocks to suit the respective machine. The advantage: they can be expanded or modified without great effort during further use.

There is currently no alternative to modularisation in mechanical engineering, as the corresponding concepts aim for a portfolio with less variance and complexity as well as an overall lower cost level without reducing the breadth and individuality of the offering (1). This statement is easier to understand when you consider the typical requirements for manufacturing systems:

Concepts such as "individual products" and "Industry 4.0" require highly variable production systems that enable a wider range of products to be manufactured, even in smaller quantities. To this end, the systems must be scalable and offer options for subsequent expansion (2).

For mechanical engineering companies to reach their customers, it is not enough to develop and sell good products – and wait for service/maintenance orders. This is because life cycle costs (LCC) are playing an increasingly important role in the economic analysis of investments. LCC can be used to present and sell new business concepts, including maintenance, service and retrofit services, in a very transparent manner. This makes it easier for machine manufacturers to convince users of the advantages of the expanded range of services covering the entire life cycle of the plant (3). The growing demand for subscription models such as "pay per use", "pay per month" and "pay per unit" confirms this trend. After all, usage- and service-oriented models are also economically attractive: in 2018, the average margin on new machine sales was 5.4%, while for services it was 40%.(4)

Especially in the case of high-priced capital goods, it is often more economical to expand existing machines and renew assemblies than to purchase them completely new.

At least some customers expect machine modules or subsystems from different suppliers to be able to be integrated into existing systems without any special effort.

Prerequisites for modularisation

However, before OEMs decide to push ahead with the modularisation of their products and manufacturing they should be able to answer the following questions in the affirmative:

Can the estimated total cost of a new, consistently modular product group be plausibly recouped within the usual timeframe for the industry and based on worst-case assumptions for further market development?

Do all departments involved consider the challenges posed by the planned redesign of the machine or system to be feasible?

Are all affected parts of the business prepared to align their working methods with the new modular concept?

It is also important to clarify the extent to which a machine or system should be divided into modules. The genius of LEGO lies not in the building blocks themselves, but in the connections between them. These determine the possible granularity of the division, but are also the limiting factor for the connection of components. The situation is similar with the interfaces in a machine: they ensure a coherent "overall structure" by guaranteeing the proper functioning of the machine parts and production lines. The correct separation of the building blocks of the "overall system" from each other is therefore essential for successful modularisation.

HARTING's recommendations

First, structure the initial system according to functions: into key functions that reflect your core competence, basic functions (e.g. carrier or transport systems) that extend across the entire system, and add-on or auxiliary functions.

Now combine these functions into modules – but only as granularly as necessary! Take into account all aspects of possible optimisation and the necessary equipment variance. Include as many stages of service provision as possible along the machine life cycle.

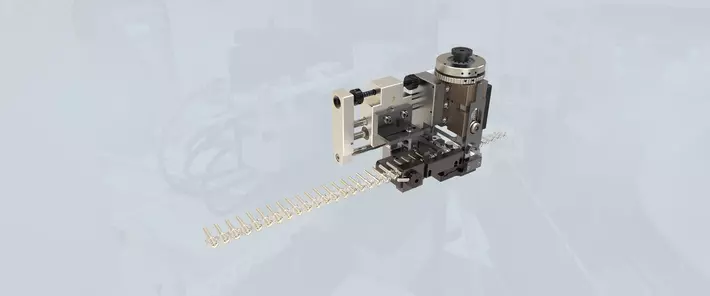

Assess the significance for the newly defined machine module of all elements of the machine that cannot be further "divided" (sensors, actuators, HMI, drives, etc.) and that require electrical/electronic power, signal or data connections.

Assign these elements to a suitable machine layer.

Assign all necessary interfaces for connecting individual elements to the respective machine modules.

The result is a matrix that lists all modules of the future system: The hierarchical arrangement of the parts, including interfaces and their module relevance, should be visible. Based on the matrix, you can evaluate the feasibility, technical risks and consequences for the design of the machine. Transparency increases when you weight the importance of the modules for the overall system. The matrix not only shows the fractions involved, but also the further steps in the development of the modules and processes.

The question of the right control system for the machine or plant can now also be answered more easily. HARTING's observations on this subject indicate that...

Systems with a high degree of variability in key functions and a large spatial extent tend to be equipped with decentralised I/O systems throughout.

Combined structures are chosen for smaller, highly variable systems. The control of key and basic functions is then set up centrally, while additional functions are controlled either centrally (simple) or decentrally (complex interfaces), depending on their complexity;

for smaller and/or simple systems with low variability, pure central control is simpler and more economical.

The relevance of interfaces

The almost absolute freedom associated with modular production systems is decisively influenced by the interfaces. The transmission capacities and options for action offered by these components help determine the modularity of the system. Therefore, the interfaces should ...

always be designed in a cost-optimised manner for the respective requirements (electrical, EMC properties) of the transmission path;

be gradually scalable in terms of technical parameters as well as size and number on each machine module;

be able to meet different requirements in terms of materials, contacting, mounting and protection types, and integrate alternative transmission media such as fibre optic cables and compressed air.

Greater efficiency through modularisation

Consistent modularisation based on the targeted optimisation of all costs and service provision processes in the life cycle (LCC model) enables the manufacture of machines according to the modular principle – with considerably less effort. At the same time, there is greater scope for customer-specific configurations. Users also benefit from modularisation, as they receive a machine that is optimised in terms of cost and requirements and at the same time transparently designed. Interfaces are a decisive factor for successful modularisation.

References

VDMA, McKinsey, 2014,

"Future prospects for German mechanical engineering" Roland Berger, 2011,

„Production Systems 2020” M. Bode, F. Bünting, K. Geißdörfer, „Rechenbuch der Lebenszykluskosten“, VDMA Verlag, ISBN 978-3-8163-0617-7

Commerzbank, 2019,

"Mechanical engineering in Germany" ID-Consult,

"Modularisation Strategy 2018/2019: The Influence of Modular Product Architectures on Corporate Success"

Jakob Dueck

Position: Industry Segment Manager Machinery

- Department: Industry Segment Management

- Company: HARTING Technology Group