Rethinking Connectivity for Lights-out Semiconductor Manufacturing

This article was originally featured in

Artificial intelligence is revolutionizing the semiconductor industry along the entire value chain — driving faster, more efficient circuit design, better predictive maintenance for tools and equipment, and optimized fab operations. While increasingly complex chip designs call for more complex manufacturing processes, those same innovations underpin the technologies — such as edge computing and agentic AI — that are helping equipment manufacturers and fabs advance toward the goal of “lights-out” operation.

Historically, in semiconductor tool and equipment design, connectivity — meaning the delivery of signal, power and data to and between subsystems — has been relegated to a late-stage design task and considered a secondary concern. The primary engineering focus traditionally went to the core process modules, such as the process chambers, vacuum systems and electromechanical assemblies, since those directly affect wafer processing and throughput. Only after those systems were defined did engineers typically address how to route cables, connectors and interfaces, leading to late-stage integration challenges.

As the industry confronts narrowing margins, both spatial and economic, this approach is no longer tenable. The requirements of contemporary fabs dictate a shift:

This transition comes with language nuances distinct to our field. While other sectors may use terms like “human in the loop” or “human discernment layer,” semiconductor fabs overwhelmingly focus on minimizing direct intervention — and recognize that certain tasks, especially complex maintenance, remain out of reach for full automation. The industry expectation is not the elimination of human operators but their targeted, expert deployment at key intervals.

Tools for manufacturing chips at advanced nodes, and the fabs in which they operate, require connectivity solutions that are modular, supporting expansion, serviceability, and redundancy,

Yield optimization: Connectivity as control lever

The legacy model, where process variability was managed by labor-intensive inspections and post-mortem analysis, has been displaced by continuous monitoring and inline metrology. Automated process control loops, created from real-time data streaming through high-reliability connectors, now monitor and control flow rates, chemical dosing and temperature settings without direct human input.

Furthermore,

While the largest OEMs in the industry are quick to adopt these practices, small and mid-tier equipment makers sometimes lag in engaging connector specialists early in the process. The missed opportunity here can be significant, since late-stage attempts to resolve connector placement or serviceability in legacy systems can hinder access and serviceability. Take, for example, the case of a hardwired subsystem with nearly 100 connections. The system not only took weeks to build and commission, but when troubleshooting was required, the system was offline for several days.

Design philosophy for serviceability and minimization of downtime

Downtime remains one of the most costly liabilities in device fabrication. Even an hour offline can mean tens of thousands in lost value. The lights-out fab, by design, seeks to convert scheduled and unscheduled maintenance events into manageable, recoverable cycles.

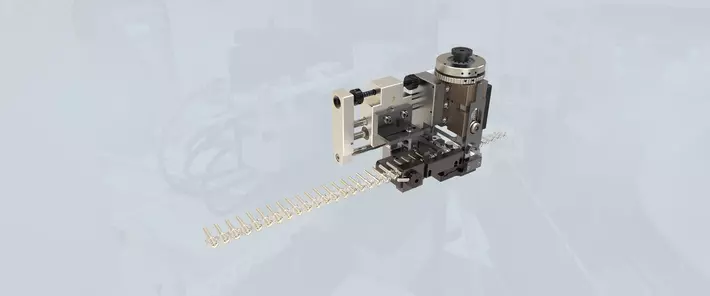

Rather than relying on hardwired point-to-point systems, a legacy that persists in some small and mid-market equipment builds, the latest trend is to embrace modular and hybrid connector solutions. These provide not only a smaller footprint but also the capability to combine power, signal and data into a single, error-proof interface. Keyed and color-coded connectors eliminate the risk of misconnection,

From an engineering perspective,

Designing for global serviceability is a concurrent reality. Many advanced fabs now require remote diagnostic access — meaning connector architecture must support easy troubleshooting, rapid information flow and fast intervention from teams located halfway around the world.

Sustainability: Realtime optimization and material stewardship

Pressure on water, energy and chemical usage is intensifying, with many regions instituting strict controls and incentives for improvement. Connectivity-rich ecosystems are now fundamental to effective sustainability initiatives,

Advanced connectivity platforms are allowing fabs to implement precision gas, chemical and water management, automating delivery systems to dynamically adjust to real-time variations in process requirements. According to recent analysis, closed-loop process control and

Such advances are not limited to regulatory compliance or cost-cutting. They also facilitate a culture of stewardship and transparency, a value increasingly demanded by investors, partners and regulators as the industry grows in both scale and influence.

Engineering out the worker safety risks

Cleanrooms, despite their pristine appearance and reputation for sterility,

The migration toward lights-out manufacturing represents an opportunity to reconfigure this risk profile. Automation technologies, enabled by reliable, diagnostic-rich connectivity, progressively replace direct human involvement in hazardous tasks, from real-time gas cabinet monitoring to fully robotic wafer handling and automated chemical supply chains. This evolution drastically reduces exposure and confines human activity to operations demanding dexterity, judgment or complex troubleshooting.

Even as robotics and cobots take on a greater share of maintenance, there are still limitations to their abilities: certain complex, precise actions, such as locating and changing out a thermocouple, will demand a human’s dexterity and judgment. But the goal of lights-out automation is to minimize – not eliminate – human involvement and oversight.

Real-time sensor networks and continuous event logging underpin these advances, providing safety managers with granular data for ongoing hazard assessment and compliance verification. The immediate benefits of these technologies are reductions in workplace accidents and exposure incidents, while strategically, they enhance company reputation and regulatory standing. Furthermore, proactive safety management grounded in precise, data-driven insights aligns operational rigor with human well-being, ensuring that as fabs scale and intensify operations, worker protections advance together with productivity goals.

Shrinking footprints, increasing demands

Semiconductor manufacturers face tighter design constraints every year,

Today’s tools aren’t getting bigger; quite the opposite, as fabs grow ever more expensive, the imperative is to pack more capability into shrinking footprints. Where engineers once filled an accessible panel with an array of connectors the size of a small billboard, the requirement now is to maintain, upgrade and troubleshoot in spaces that are orders of magnitude smaller and vastly more challenging to access.

The upshot is that connector size and capability directly impact both system performance and maintainability — for example, miniaturized connectors have become routine, allowing high-density layouts and multifunction power, data, and signal delivery in extremely compact subassemblies.

As form factors change, technical priorities shift as well. Engineers now rank reliability, contact integrity and lifecycle durability above virtually every other design characteristic, knowing that ruggedized, robust connectors are essential to maintaining uninterrupted operation amid continuous use and various environmental challenges. Yet robustness is just one part of the equation — innovation now focuses on modular and hybrid architectures, flexible platforms that optimize how inserts, housings and locking mechanisms interact, supporting faster assembly, commissioning, and maintenance. Connectorized solutions have, in industry surveys,

Miniaturization also fundamentally changes how error-proofing and operational integrity are achieved. In lights-out fabs, every connection point must guard against misalignment or faulty mating, by human or robot. Keyed housings, color cues and tactile guidance are no longer best practice but basic requirements; automated diagnostics, sensor-driven feedback and real-time data transmission enable systems to recognize potential issues and call for intervention before failures disrupt production. Fast troubleshooting, including connectors with integrated fuses, enabling automated systems to detect and resolve faults without requiring physical access to the cabinet, is rapidly replacing scheduled maintenance cycles, supporting uptime and automation goals.

The practical realities remain: engineers may be tempted to “copy and paste” their last design, but rethinking connectivity can produce future tools that are more easily serviced, robust and scalable. Vendors who co-design with tool and equipment manufacturers help ensure that new designs include user-friendly, maintainable connectivity solutions that support the sensors, monitors, and data collection devices that underpin the move to lights-out operation.

Ultimately, the constraints imposed by miniaturization and rising costs have forced a fundamental rethink of how fabs connect, integrate and maintain their systems. The new design paradigm emphasizes compactness, modularity and error-proof reliability — engineered to support the growing complexity of the next-generation fab. Size constraints and integration needs aren’t peripheral; they’re now central to the semiconductor manufacturing strategy, which includes lights-out operation.

Connectivity solutions enabling lights-out manufacturing

The semiconductor industry’s evolution toward fully integrated, data-rich and highly automated manufacturing environments represents a redefinition of design priorities. Connectivity, once a supporting function, has become the critical infrastructure on which every element of fab performance depends. It governs how tools communicate, how data flows and how quickly systems recover from disruption.

By embedding connectivity early in design, equipment makers and fab operators gain speed and precision, but also resilience; the ability to adapt systems dynamically to new processes, materials and regulatory expectations. The most advanced fabs will no longer treat interconnects as passive conduits, but as active, intelligent interfaces that enable continuous monitoring, predictive control and sustainable operation.

As the industry pushes deeper into lights-out automation, every connection becomes a potential source of insight and advantage. Designing for that future means viewing connectivity not as an endpoint of engineering, but as a key foundational piece of the overall system design.

Danielle Collins

Position: Global Segment Manager

- Company: HARTING