Year in Review: Connectivity Trends Shaping 2025

1. AI Everywhere Drives Smarter Industrial Infrastructure

The "AI-ification" of society has left its mark in almost every facet of modern life and is at the forefront of today's drive for smarter industrial processes across industries. In healthcare, finance, manufacturing, and other sectors, AI's promise of lighter workloads and faster data processing is changing work and life at an unprecedented pace.

But AI demands ultra-fast, reliable, and low-latency connectivity and massive power usage from data centers to deliver on these futuristic promises.

"Data center infrastructure must evolve rapidly: becoming not only larger, but smarter, faster, and greener," says HARTING's data center connectivity expert, Will Stewart. "Every connection system and square foot now counts in the race to keep up with exponential demand."

To keep up with these demands, data center hyperscalers are adopting hybrid scaling strategies — scale-up, scale-out, and scale-across — requiring flexible connector solutions that can keep pace with evolving architectures.

Read More:

2. Power as the New Bottleneck

With AI and high-performance computing consuming more energy than ever, power distribution has become a critical challenge. Data centers are moving to higher voltage architectures (+400VDC and +800VDC) and deploying power sidecars to handle escalating loads. Modular, connectorized solutions built for these power requirements are enabling faster installation and reducing labor bottlenecks, ensuring facilities stay ahead of demand.

"Data Centers [alone] must deliver far more power to denser racks, operate reliably under heavier loads, and deploy new capacity at speeds unimaginable even a decade ago," adds Stewart. "These requirements are putting immense pressure on every inch of physical infrastructure, from the electrical grid connection to the server cabinet."

In other sectors, like energy distribution, energy transmission, semiconductor manufacturing, and manufacturing, the race for more, reliable power mirrors the gold rush. We're already testing the limits of aging energy infrastructure, so new forms of energy creation are a must to power the future, as are solutions that help use today's available power more efficiently.

New and improved components must accelerate the timeline to deploy energy generation sites to meet future demand.

Read More:

3. Modularity for Future-Proof Flexibility

Across industries, equipment modularity has moved from nice-to-have to an essential feature. In data centers, connectorized rPDUs, modular power shelves, and pre-assembled cable assemblies have replaced hardwiring, cutting deployment times from weeks to days. This approach delivers flexibility, scalability, and cost efficiency for data centers, automation systems, and mobility platforms alike.

In manufacturing, equipment architecture that can be reconfigured for different process needs offers flexibility needed in today's constantly-evolving marketplace. In semiconductor manufacturing, this modularity has even been called "The Holy Grail."

"Modular connectors let electrical engineers combine power, data, and signal connections into a single unit," explains HARTING's Danielle Collins. "This integration reduces the space needed for connectors and cables, providing significant design flexibility."

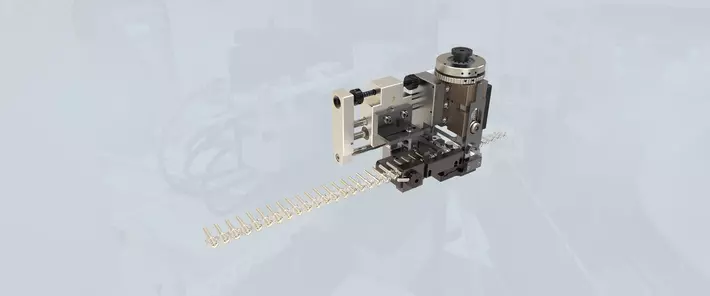

To enable this modularity, engineers use modular connectors (like HARTING's standby

Read More:

4. Miniaturization Meets High Performance

Cramming more functionality in less space is one way to make industrial equipment more efficient. Just miniaturization has driven innovation in everything from phones to vehicles, connectors continue to shrink footprint while improving performance of power, data, and signal transmission.

Solutions like HARTING's

“Design engineers are leveraging smarter technologies to optimize every detail, while shrinking the connectivity footprint that powers these innovations," says HARTING connectivity expert, Emily Kenny. "Automation and smart technology don't have to come with the sacrifice of space.”

Read More:

5. Cross-Industry Innovation Sharing

As industries see more shared challenges (read #2 trend about the power bottleneck) and sustainability goals, they are borrowing solutions from other industries.

The liquid cooling technology which has been used in EV charging for years is now being adapted to cool the cable assemblies in the always-on racks of hyperscale data centers.

Data tracking and analysis from high-tech industries has made its way to add intelligence to the everyday manufacturing floor and for balancing a smarter energy grid.

High-power connectivity innovations from railway are now being leveraged by other industries to deliver upon increasing energy demand.

At HARTING, we thrive on this kind of creative problem-solving — leveraging expertise across industries to build smarter, safer, and more scalable industrial outcomes.

Looking Forward: Connectivity Contributes to Future Innovation

Connectivity has moved beyond linking devices to enable speed, scalability, and sustainability in a world where every second counts. At HARTING, we’re committed to delivering modular, reliable, and future-ready solutions that empower businesses to thrive in this connected era.

Bryan Young

Position: Digital Marketing

- Department: Americas Marketing

- Company: HARTING