Industrial automation for efficient processes

ELROTEC combines experience and the latest technologies in the development of customised automation solutions for industry. More effective operating processes result in increased safety and cost savings.

Consistent industrial processes present companies with major challenges. The family-owned company ELROTEC from Germany supports its customers with customised robots and logistics solutions for automation. From individual work steps to complete process chains. By working in partnership with HARTING, the company ensures its long-term success in the market.

Web-Seminar | The key to modular, scalable architectures and high productivity

The seminar will explore success factors for machine manufacturers, including modular methods, valuable interfaces, and the role of digital twins.

Automate processes profitably

Many years of experience in cross-industry fields characterise ELROTEC and ensure well-founded expertise. Its customers include large corporations as well as medium-sized and individual companies, which enables a wide range of projects to be realised. The focus is on flexibility and individuality, which means that projects of all sizes can be successfully realised.

ELROTEC also conducts research, for example at the Bremen Institute for Production and Logistics, and benefits from the latest scientific findings to help develop innovative solutions and drive technological progress.

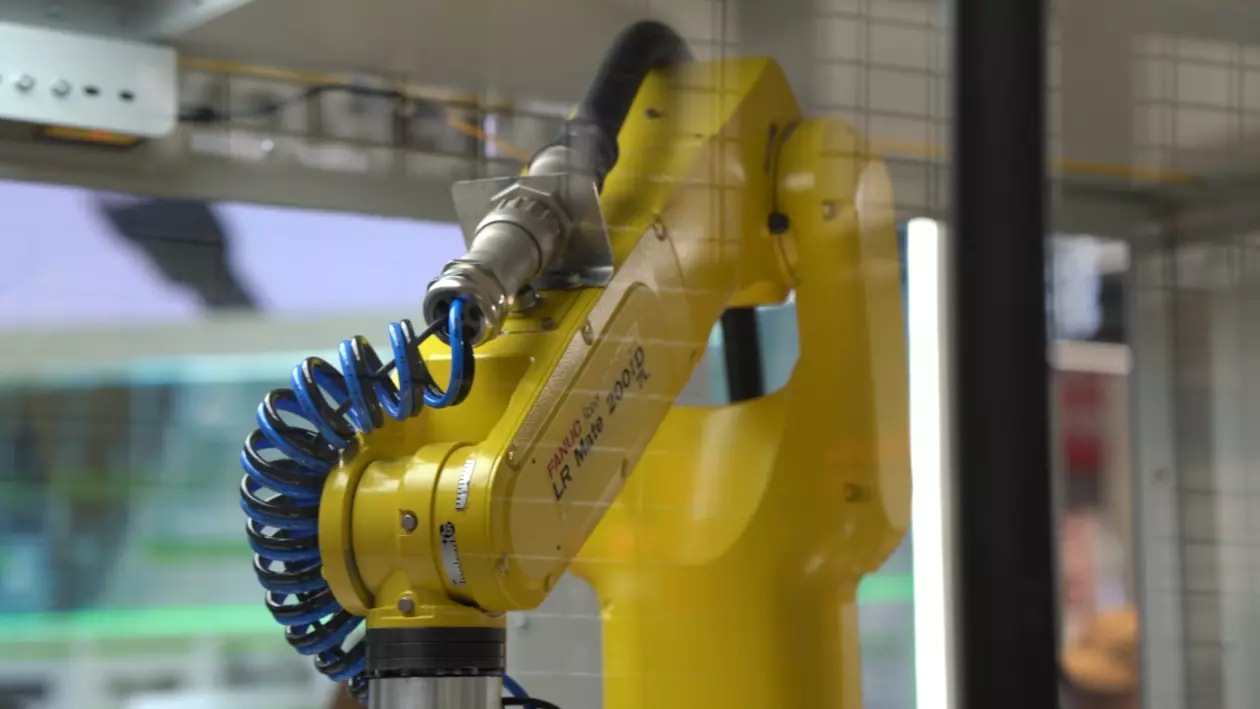

Impressions from the video

Robots enable efficient operating processes

The individual customer requirements for automation and robotics solutions are as diverse as the various areas of application in industry. The focus here is primarily on efficient operating processes, as companies are constantly striving to increase their output and optimise the use of resources. The shortage of skilled labour and the error-prone nature of monotonous tasks require this, not least in order to avoid economic damage.

Every day, ELROTEC faces the challenge of developing long term solutions, which are reliable and require little maintenance in order to meet the needs of its customers.

With extensive knowledge of the international market, the company finds optimum technical solutions for individual process steps as well as for complete process chains, enabling a customised approach. Targeted modification of the systems and robots allows them to be seamlessly integrated into the business environment, ensuring smooth implementation into existing systems.

This allows processes to be profitably automated and optimised in the long term, which not only increases productivity but also contributes to the competitiveness of companies.

Flexible design of robot dresspacks

The use of robust and efficient components is crucial to ensure reliable automation processes. ELROTEC specialises in seamlessly integrating automated solutions into overall operational processes. The use of reliable industrial connectors helps the system integrator to achieve these goals.

With the

Its design enables efficient solutions for power, signal and data transmission. It is suitable for drives, vibration-protected camera connections via

ELROTEC Managing Director Karl-Heinz Kösters is convinced that long-term co-operation with partners and suppliers such as HARTING is a decisive factor in achieving long-term success in the market and remaining competitive.

Flexible and scalable circular connectors in harsh environments

Modular architectures and high productivity are the key to success in mechanical engineering and robotics. Flexible and reliable interfaces are essential in paving the way.

Customer benefits at a glance:

Flexible integration thanks to high-quality industrial connectors that enable seamless adaptation to existing systems

High reliability and low maintenance costs thanks to robust connectors designed for harsh operating conditions

Increased process reliability thanks to the tested quality of the connectors, which comply with strict industry standards

Versatile use of the connectors for various applications in automation technology

Time savings thanks to simple installation and faster tool changes

In the past, we often had space problems with circular dresspacks. With the ICC 20, we now have a modular, flexible solution for these requirements. We also had difficulties with RJ45 connectors due to vibrations. The industrial-grade SPE integration offers significant advantages here. The 400 A contact inserts also allow high-performance welding processes to be automated profitably. The variety of possible inserts and termination technologies makes it easier to change tools.

Karl-Heinz Kösters

CEO | ELROTEC GmbH