Front End Semiconductor Tool and Equipment Connectivity

From lithography to deposition and etch, front end tools perform the most critical processes that create the circuits on silicon wafers. These steps include adding and removing materials on the wafer with sub-micron accuracy, demanding seamless connectivity across power, data, and signal interfaces to ensure uninterrupted operation and real-time communication.

There's no time for downtime.

In the ultra-complex world of semiconductor manufacturing, connectivity isn’t just a detail, but a critical safeguard for uptime, yield, and profitability.

With the cost of a 2nm wafer reaching $30,000 or more and target production of 40,000 wafer starts per month, leading edge fabs can’t afford downtime. Even a few minutes can translate into hundreds of thousands of dollars in lost revenue. For tool and equipment manufacturers, this means reliability and uptime are paramount, and high-speed, continuous monitoring is essential.

Space is at a premium

As fabs push to put more equipment in the same — or less — space, compact, modular connectivity enables tool designers to deliver more power and data in less space.

This is why semiconductor tool and equipment manufacturers have turned to HARTING's compact and reliable connector solutions to maximize uptime and profits.

Front End Semiconductor Applications

Controls

Smarter controls start with smarter connectivity.

In semiconductor fabs, machine controls are the brains behind every process. Many OEMs build their own control systems to meet the unique demands of their tools. But custom doesn’t have to mean complicated.

Flexible, high-performance connectors streamline the design and assembly of control electronics, helping teams build faster, test more reliably, and scale with confidence.

The HARTING

Data & Signal From Sensors

Real-time data for real-time demands.

Semiconductor tools rely on a constant stream of real-time data — including temperature, vibration, pressure, and flow — to control, analyze, and optimize the process. These metrics are captured by sensors embedded throughout the equipment, often across multiple chambers that must communicate seamlessly with each other and with the fab’s master control systems.

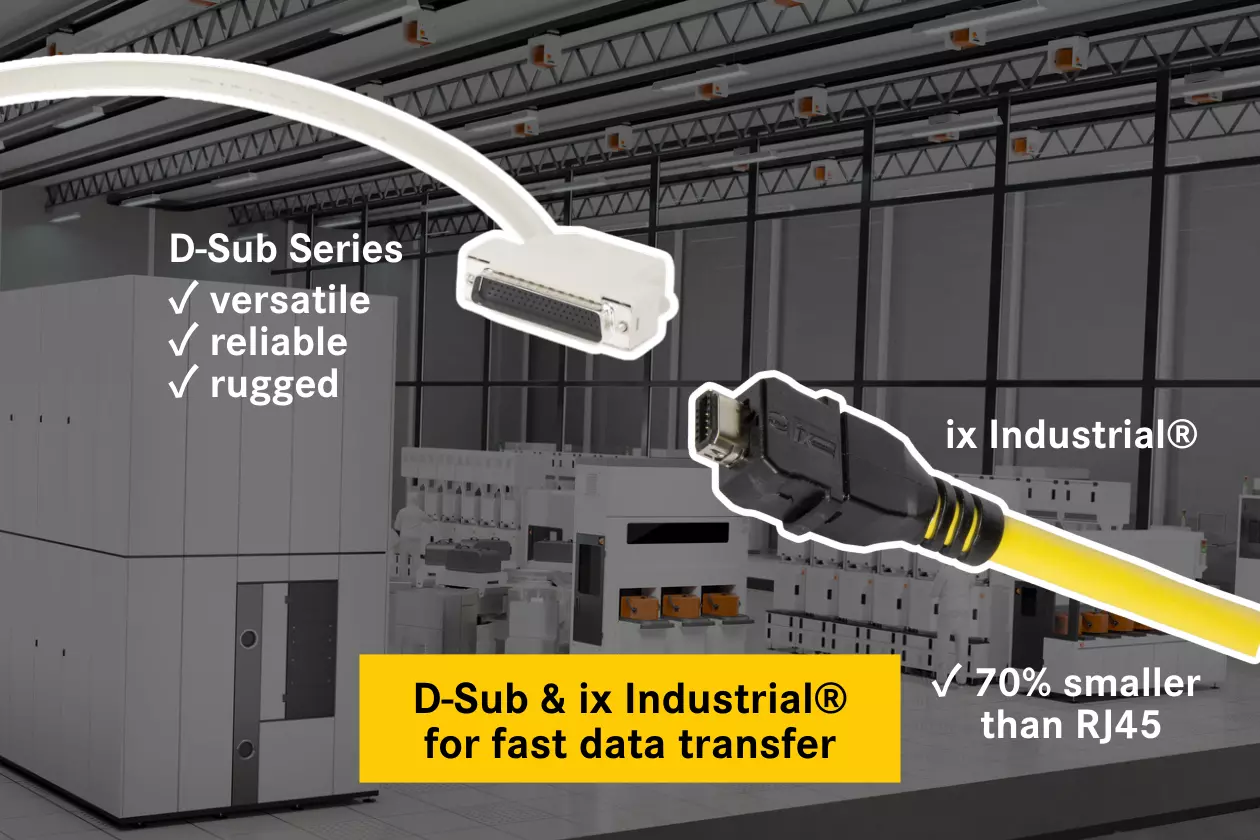

In this environment, connectivity is the backbone of performance. When footprint is limited and uptime is critical, choosing the right connector provides a strategic advantage.

HARTING’s

Power

Power boxes for tools and systems.

In a fab, nothing runs without power. Every tool, chamber, motor, and sensor needs reliable power to operate. But as the power requirements of tools and equipment have increased, the available space for reliable, robust connectors has decreased.

HARTING meets this demand for more power in a smaller footprint with connectivity solutions such as the

More Semiconductor Resources

Better Connectivity in the Small Footprints of Semiconductor Manufacturing

From smartphones and smartwatches to autonomous vehicles and AI servers, semiconductor chips can be found in devices everywhere. To keep up with the demand for these chips, semiconductor manufacturing equipment must produce more chips without requiring more from existing facilities.

Increasing yield without expanding the equipment footprint requires smarter, more efficient machines.

Modular connectors simplify complexity. Just like HDMI replaced RCA cables in consumer electronics, modular industrial connectors consolidate multiple functions into a single interface.