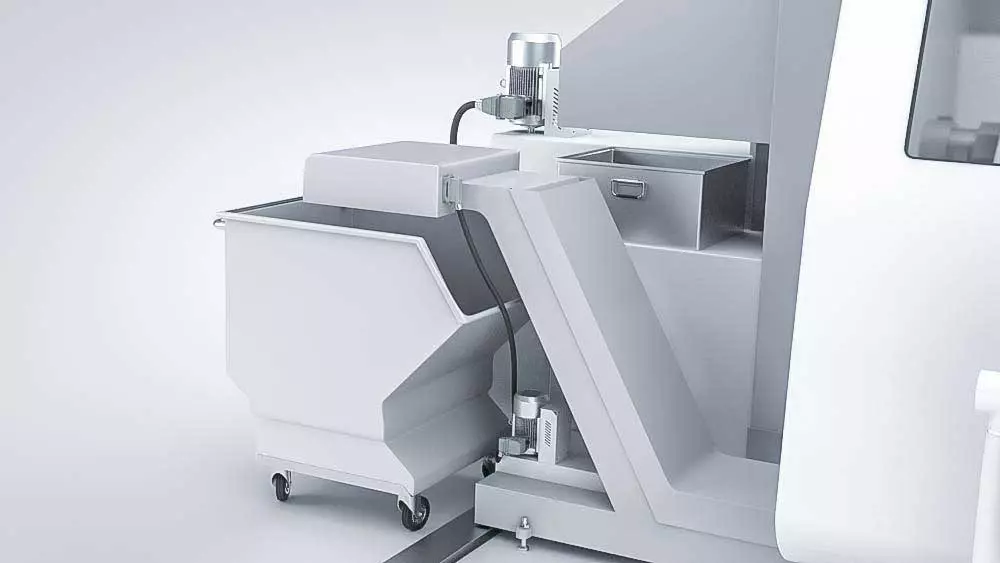

Chip conveyors and filter systems are typical systems in metalworking machines: They remove metal chips and swarf during machining and filter the coolant to return it to the process. These integrated systems increase efficiency by automating chip removal and maintaining coolant quality. This increases process reliability, reduces downtime, and lowers environmental impact.