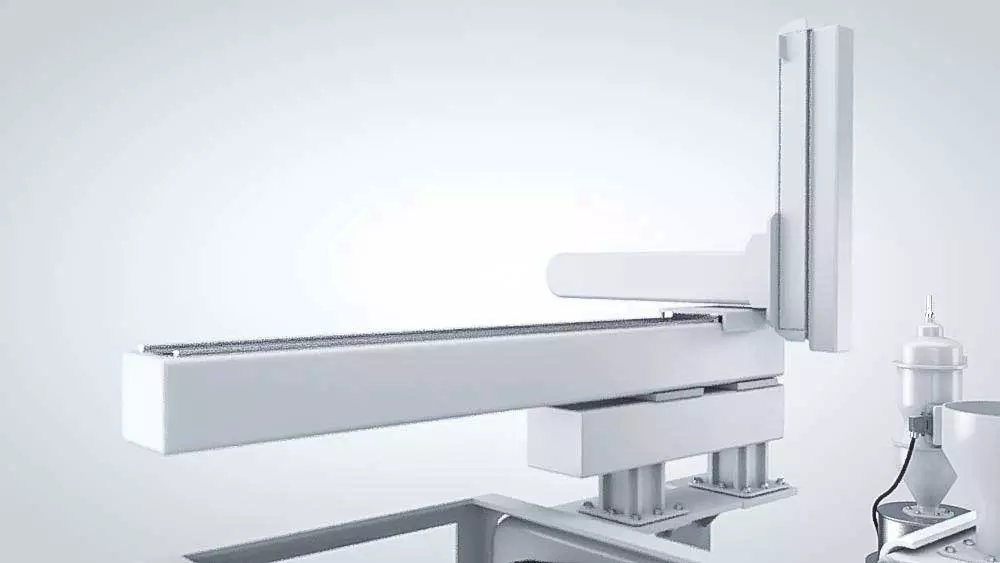

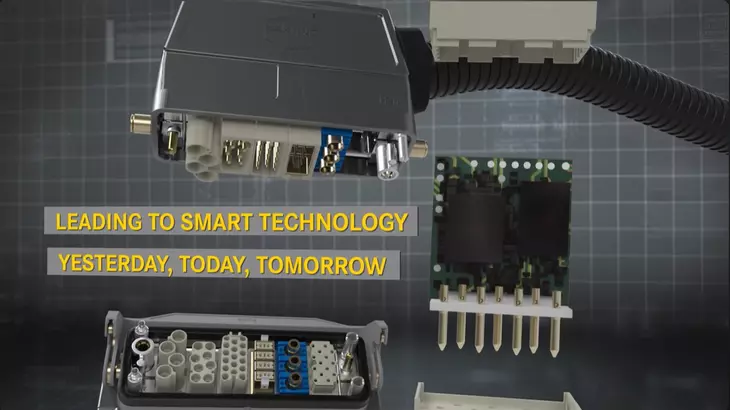

Plastic injection moulding tools (dies) are highly complex technical units today: depending on the end product, different plastic components may be used, or several components may be integrated into the final product. To ensure consistently high-quality manufacturing processes, these tools are equipped with various types of sensors as well as heating and cooling systems.

The interfaces for these injection moulding tools must meet a wide range of requirements:

they must be scalable and flexibly adaptable,

capable of transmitting a large number of signals and media,

able to function reliably over the long term under extreme conditions, such as high temperatures and mechanical stress.