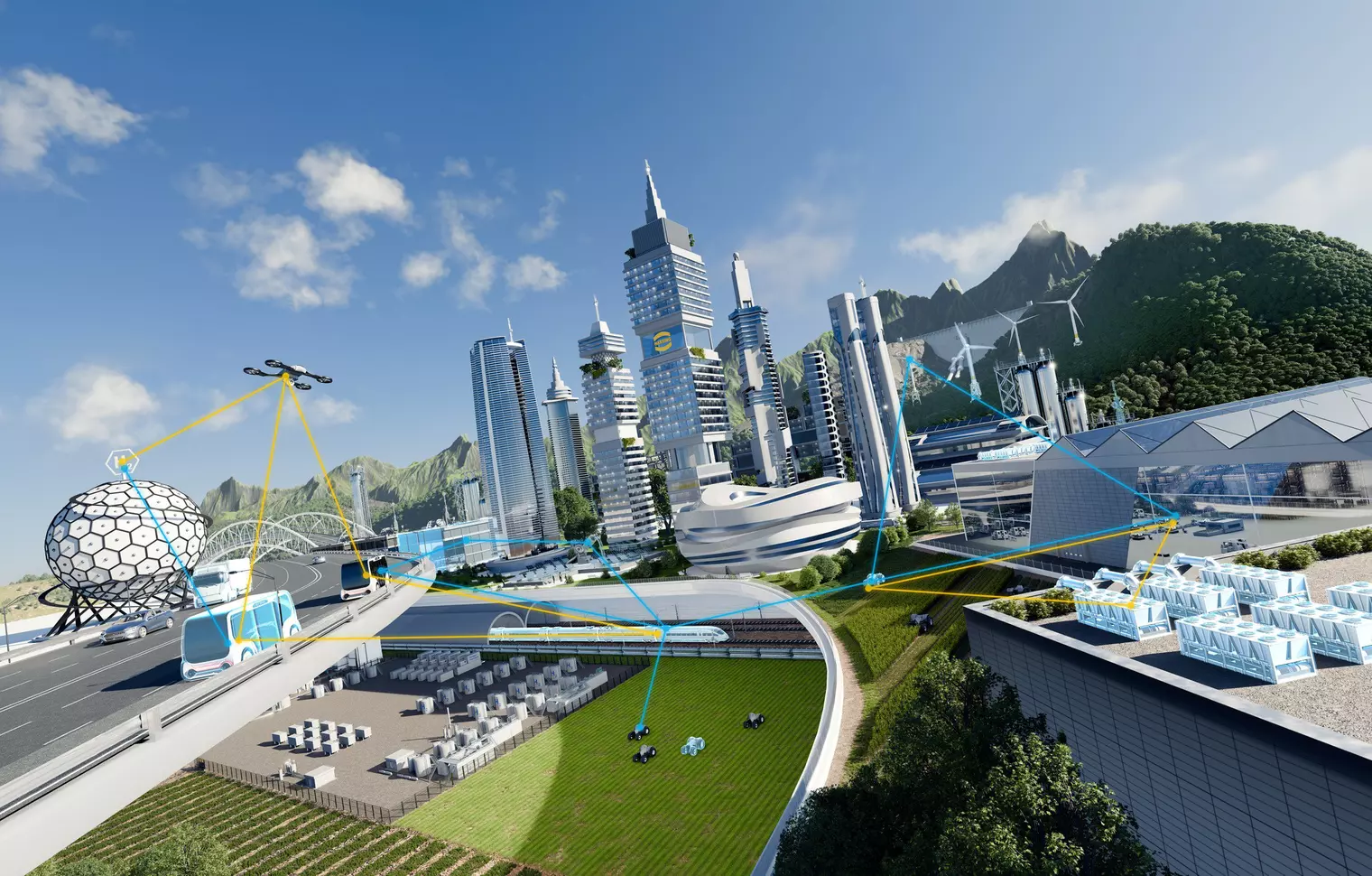

HARTING Energy Transition Days 2025 (APAC Ed)

Join the Asia-Pacific Energy Transition Days (24–25 September)! Register once to freely attend all sessions and explore the future of power grids, hydrogen energy, energy storage systems and data centres.