Back End Semiconductor Equipment Connectivity

The diverse equipment used in back end processes relies on rugged, compact connectors that deliver uninterrupted power, data, and signal flow. In the systems where final testing, packaging, and assembly take place, new technologies can speed processes and find new efficiencies. Plug-and-play, smart, modular, and hybrid connectors, help streamline installation, reduce maintenance, and future-proof operations for evolving production needs.

Reliable connectivity for high-performing back end automation.

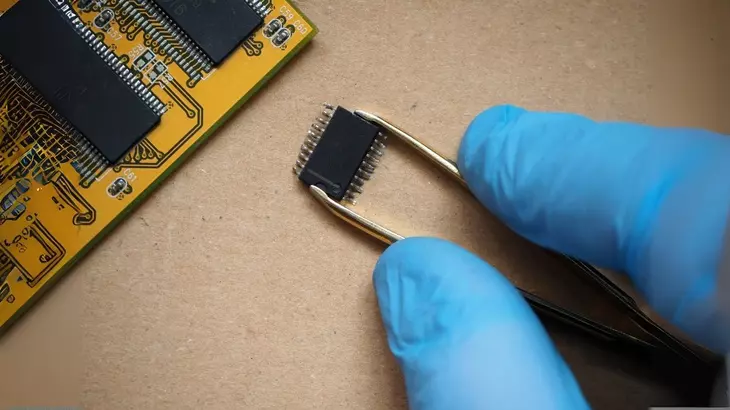

Back end semiconductor operations — packaging, assembly, and test — rely on electromechanical precision and high-speed automation.

From Cartesian robots executing rapid pick-and-place movements to finely tuned inspection systems, every machine depends on fast, accurate control signals and uninterrupted power and data flow. And when those connections are in constant motion, you need connectors and cable assemblies built to endure.

Here’s what rugged, reliable connectivity delivers:

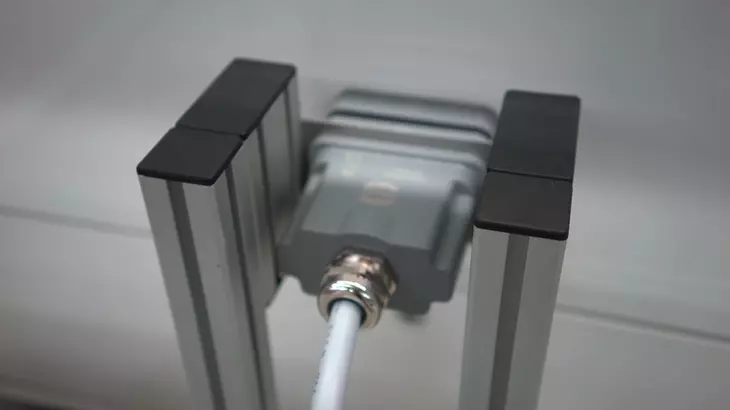

Increased uptime and reduced maintenance costs, even in vibration-prone environments

Faster installation and simplified field termination with plug-and-play designs

Hybrid connectors that combine power and data in one compact interface

EMI shielding and Cat.6A support for high-speed Ethernet and signal integrity

HARTING’s custom cable assemblies are engineered to meet the demands of high-speed, high-precision automation. These full cable solutions withstand constant movement, support modularity, and integrate seamlessly into existing control architectures.

Plus, with collaborative support from engineers with experience in semiconductor manufacturing, you get the help you require to eliminate risk, streamline deployment, and scale confidently.

Semiconductor Fab Connectivity

More Semiconductor Resources

Better Connectivity in the Small Footprints of Semiconductor Manufacturing

From smartphones and smartwatches to autonomous vehicles and AI servers, semiconductor chips can be found in devices everywhere. To keep up with the demand for these chips, semiconductor manufacturing equipment must produce more chips without requiring more from existing facilities.

Increasing yield without expanding the equipment footprint requires smarter, more efficient machines.

Modular connectors simplify complexity. Just like HDMI replaced RCA cables in consumer electronics, modular industrial connectors consolidate multiple functions into a single interface.