Semiconductor Inspection & Testing Connectivity

In the inspection and testing phase of semiconductor manufacturing, precision and reliability are non-negotiable. Every signal, sensor, and control system must operate flawlessly to validate performance and ensure zero-defect output. That’s why fast, secure connectivity is essential — to keep quality control systems running smoothly and maximize yield.

Inspection and quality control systems with precision and speed.

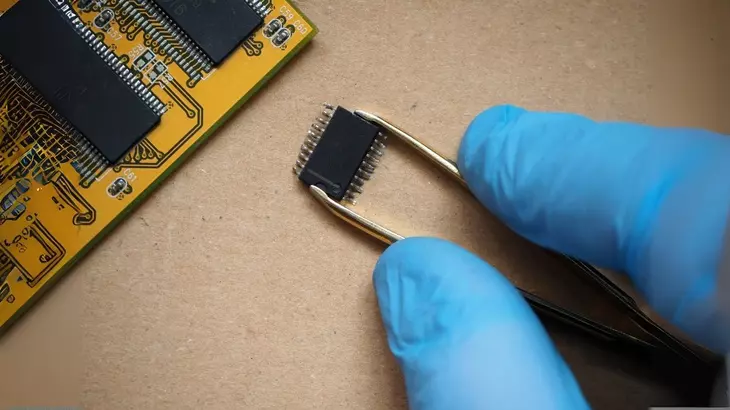

During the inspection and testing phase, wafer and reticles undergo rigorous validation to ensure they’re defect-free and meet dimensional and functional requirements before further processing. This includes probing, optical inspection, and functional verification, often performed by high-speed automated systems that rely on precise electromechanical motion and real-time data feedback.

With advanced chip designs and shrinking technology nodes, processing or material defects as small as a few nanometers can scrap an entire wafer or reticle.

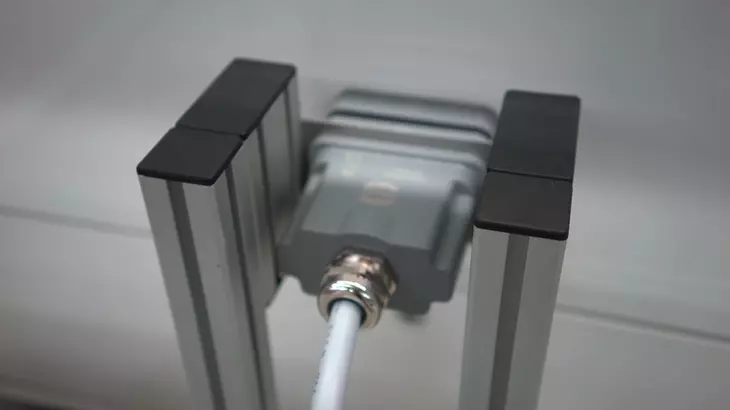

That’s why fast, secure transmission of power, signal, and data is essential. And why cable assemblies must be engineered to withstand constant movement, vibration, and EMI exposure.

Smaller, smarter connectors help inspection and testing systems by:

Reducing equipment footprint for more compact test stations

Supporting hybrid power + data transmission to simplify wiring

Enabling faster installation and field termination with plug-and-play designs

Minimizing signal loss and EMI interference for accurate test results

Withstanding repetitive motion and high-speed cycles without degradation

HARTING’s connectors and custom cable assemblies are designed to meet these demands, offering rugged, modular solutions that integrate seamlessly into automated inspection systems. We understand the full cable architecture, not just the connector, helping you build smarter, more reliable test environments.

Semiconductor Fab Connectivity

More Semiconductor Resources

Better Connectivity in the Small Footprints of Semiconductor Manufacturing

From smartphones and smartwatches to autonomous vehicles and AI servers, semiconductor chips can be found in devices everywhere. To keep up with the demand for these chips, semiconductor manufacturing equipment must produce more chips without requiring more from existing facilities.

Increasing yield without expanding the equipment footprint requires smarter, more efficient machines.

Modular connectors simplify complexity. Just like HDMI replaced RCA cables in consumer electronics, modular industrial connectors consolidate multiple functions into a single interface.