Semiconductor Manufacturing Subfab Connectivity

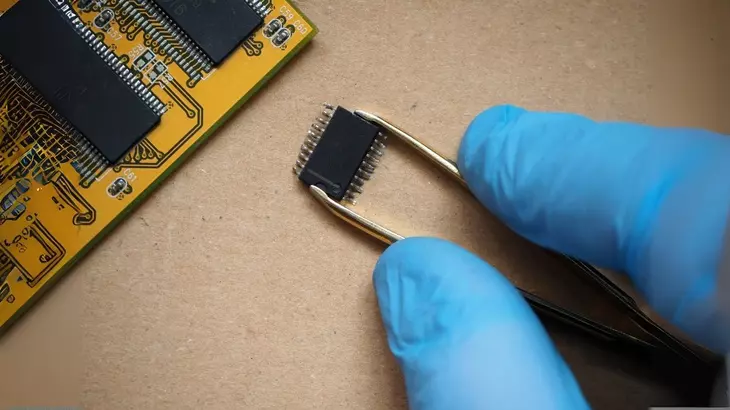

Beneath the pristine environment of a semiconductor cleanroom lies the subfab and the critical infrastructure layer housing machines such as power distribution units, vacuum pumps, abatement systems, chillers, and gas delivery units. These systems are essential for maintaining process integrity, safety, and uptime. Reliable connectivity across power, data, and signal is vital to ensure these machines function seamlessly and communicate reliably with the tools in the cleanroom above..

Reliable power supply keeps fab infrastructure online.

The subfab is where the real orchestration of semiconductor manufacturing happens, and its complexity rivals the fab itself. In addition to supporting the process tools and equipment, subfab systems are also critical for ensuring the efficiency and safety of the fab.

In the subfab, connectivity solutions that provide high-speed data transfer and reliable power distribution are key for supporting mission-critical equipment and systems.

Billions at stake: Building a leading-edge fab can cost $10–$20 billion, making uptime and reliability non-negotiable.

Energy-intensive operations: A single fab can consume 100 megawatts or more of power each hour, equivalent to powering a small city.

Thousands of systems to manage: The subfab contains vacuum pumps, gas delivery, chemical systems, cooling, and other critical infrastructure, all running in harmony 24/7/365.

HARTING’s connector portfolio is built for this environment by offering:

Plug-and-play flexibility to simplify installation and reduce downtime

Rugged construction for continuous delivery of high voltage and current

Custom cable assemblies to meet your specific power, footprint, and environmental requirements

Semiconductor Fab Connectivity

Subfab Connectivity Applications

Power Delivery

Meet the never-ending demand for more, always-on, high-voltage power.

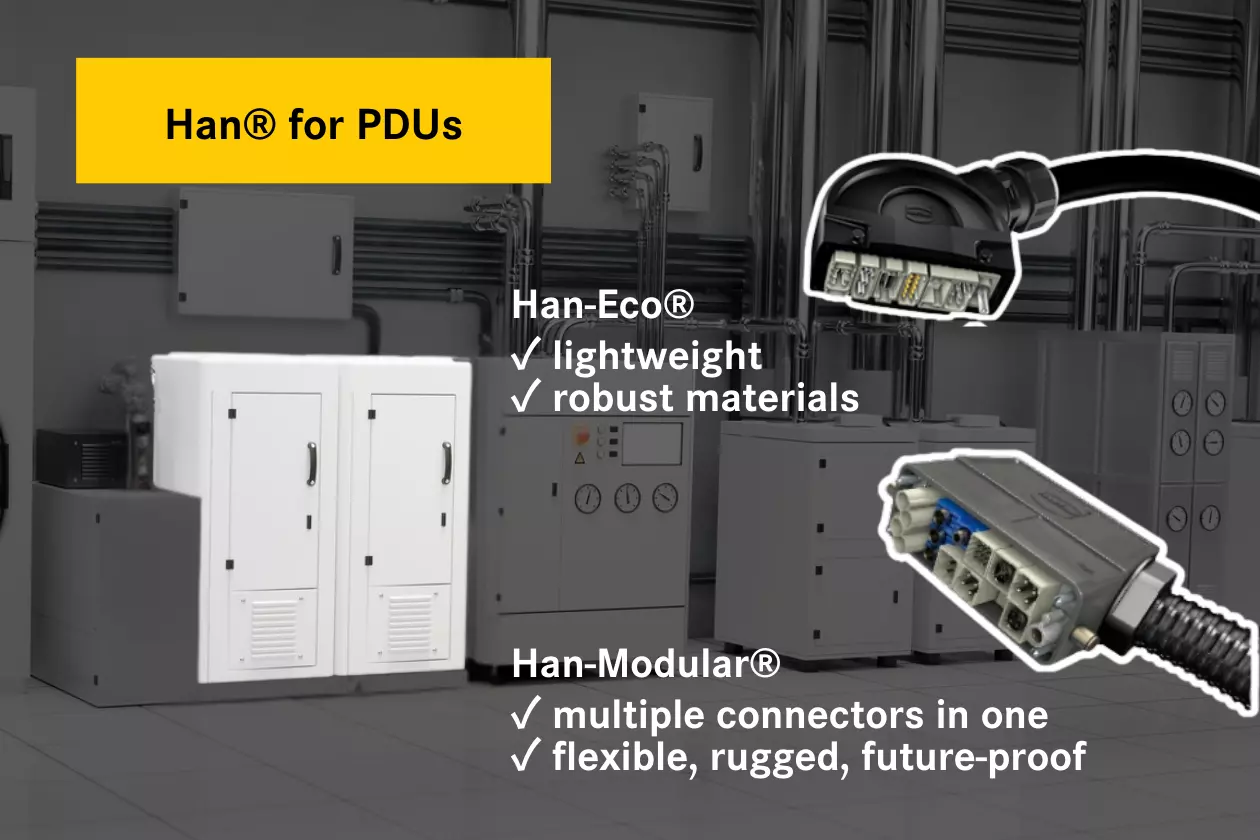

If a subfab is the brains for semiconductor manufacturing, the Power Distribution Units (PDUs) serve as the nerve center, routing energy to thousands of components that must operate in perfect sync at all times.

A single hour of power disruption can cost fabs millions of dollars in lost productivity so power connectors must withstand continuous use without compromising performance.

HARTING’s

Vacuum Systems

Precision under pressure.

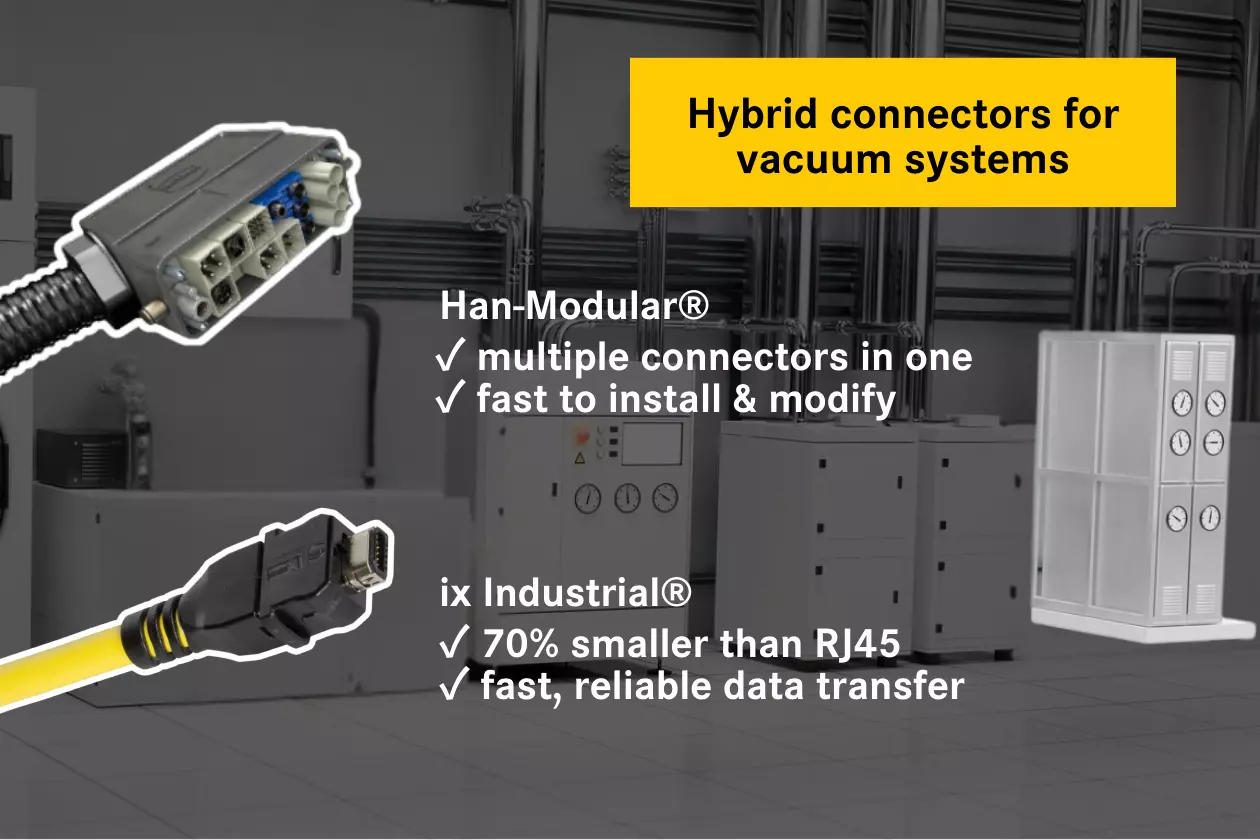

Vacuum systems regulate pressure, remove contaminants, and enable precise environmental control across multiple chambers. These systems must operate continuously and flawlessly to support the cleanroom and wafer production.

Vacuum pumps, valves, and sensors must communicate in real-time with master control systems. Rugged, modular connectors like

Lighting, HVAC & Security Systems

Connectors make lighting, HVAC, and security systems more efficient, contributing significantly to energy savings and operational effectiveness.

Connectors facilitate easy installation and replacement of lighting and HVAC components by allowing for quick connect and disconnect capabilities. This reduces downtime during maintenance activities, ensuring that systems remain operational and that energy isn't wasted due to prolonged outages.

Other benefits include:

✓ The adaptability of connectors provides design flexibility and future modification without requiring rewiring or system overhauls

✓ Smart connectivity enables real-time monitoring and adjustments to optimize energy usage

✓ Secure, reliable connectivity leads to improved uptime and utilities cost savings

✓ Efficient systems reduce carbon footprint of facilities, aligning with sustainability goals and regulations

More Semiconductor Resources

Better Connectivity in the Small Footprints of Semiconductor Manufacturing

From smartphones and smartwatches to autonomous vehicles and AI servers, semiconductor chips can be found in devices everywhere. To keep up with the demand for these chips, semiconductor manufacturing equipment must produce more chips without requiring more from existing facilities.

Increasing yield without expanding the equipment footprint requires smarter, more efficient machines.

Modular connectors simplify complexity. Just like HDMI replaced RCA cables in consumer electronics, modular industrial connectors consolidate multiple functions into a single interface.